Gear jammin

Back in the day, The General provided first gen Camaro owners a wide range of choices in final drive ratio. I’ve seen everything from high 2.xx’s to low 5.xx’s available as factory options.

For this thing in 2013 STX trim I went with 4.88, which netted high 60’s mph at the top of second gear with the original redline and rear tires I’d chosen. About right for an STX car. With eventually shorter rear tires and a lower redline after a lot of broken valvetrain parts, the max speed ended up in the low 60’s, not so good.

Another shortcoming revealed itself the following year when I took the car on the freeway for the first time – with the >27″ tall vintage tires, 4000rpm in top (fourth gear, 1:1), netted 62mph. Not very relaxing.

Not looking to track the car any time soon, I only had two requirements of the gearing situation:

- Produce the right top speed in second gear for autocross use

- Produce a reasonable cruising RPM for any trips on the freeway

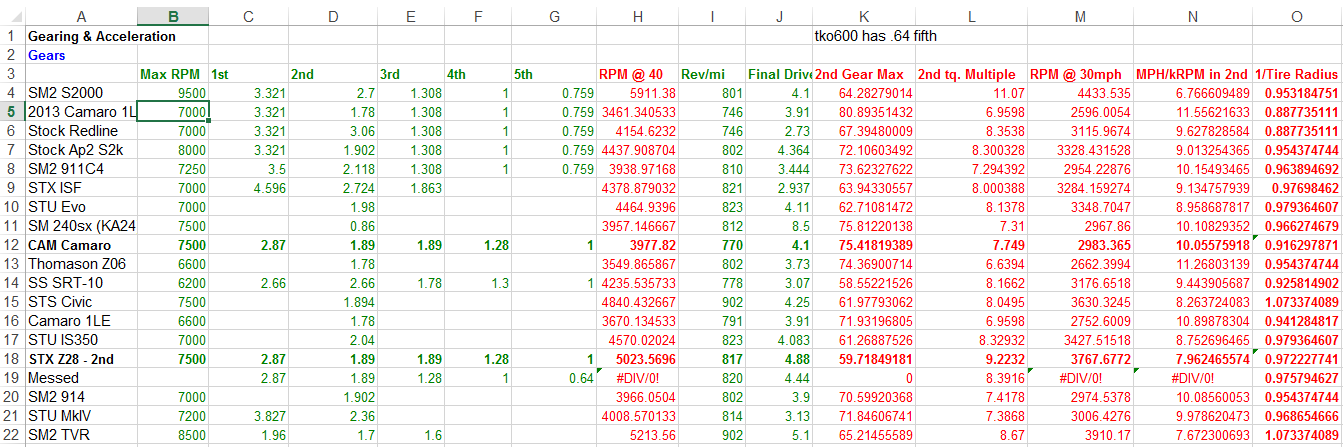

Below is a cut from one tab of my super-duper everything-I-know-about-cars spreadsheet. Getting gearing right is important and key to understanding thrust. By messing with the stuff in green I can see the resulting outputs. Column K, 2nd Gear Max, is important to ensure your car has “long enough legs” for autocross. Column M, RPM @30mph, tells you about where the engine will be coming off the slowest of corners – especially important for peaky or boosted engines. Plugging the highest transmission ratio into the second gear column and them multiplying column M by 2-2.5, gives me a quick idea of cruise RPM.

The problem with the old school Muncies is second gear (1.64 typical) tends to be too close to top gear (always 1:1). So while 10mph per 1000rpm is perfectly reasonable for second gear (column N), with a Muncie that means you’re only getting 16.4mph per 1000rpm in top – which puts you in a situation like the above.

This is where the world kinda explodes for me. Every car I’ve monkeyed with in the last 15 years, has been done within the tight constraints of an autocross ruleset. The only exception maybe was building the 240sx for Street Mod in 2007, where sizing and building a turbo system was a ton of fun – but where I also learned that there was such a thing as too hardcore of a race car for me. Every time before and since, the rules had kept me from going too far – and in my current frame of “just don’t do anything that’s illegal in CP or CAM” – the sky is the limit.

One option would be to stick with the Muncie. To produce a good autocross gear and a decent highway gear, would mean having to autocross in first gear. For regular Solo that might kinda work but for anything with a launch it would not. The little 302 just doesn’t have the beans to get off the line with a 70+mph first gear. An 8 liter Viper with a 60mph first barely does.

Another is the Gear Vendors overdrive unit, which adapt to the Muncie and give a quick overdrive at the touch of a button. Thought about this for a while, and it might be neat in an autocross setting, to basically be able to paddle-shift up or down on course between second gear and “second-over”. The biggest concern I had with this, is the “upshift” into overdrive wasn’t instantaneous (“down”shifts out of OD are) – the engagement of overdrive is actuated by a pump on the transmission output shaft, and the faster it’s turning, the quicker the engagement. In videos where they show it engaging in first gear, there’s a delay of maybe three quarters of a second before it kicks in. That maybe doesn’t sound like a long time, but when you’re trying to time that on an autocross course, it’s an eternity. Seemed likely that it wouldn’t be totally consistent either.

The other issues were the unit is pricey (more than a good new 5 speed trans) and the overdrive is “only” .78. Better than nothing, but not as much of an overdrive as offered elsewhere. Lastly, my M21 leaked like oil was going out of style. Not an easy fix either, a worn countershaft hole in the case, the only way to repair is to drill out the hole and put in a new bushing, or buy a whole new case. So to fix the M21 and do the GV Overdrive was quickly becoming a $4k proposition

Elsewhere, there are some really beefy 4 speeds, like the Jerico transmissions commonly used in circle track racing. Common now in Street Modified and Prepared classes autocross, they are strong and light, and for this common RWD Chevy application, not that much more than some of these other options. Their non-synchronized straight cut gears sound great too. Problems there, they’re quite noisy, a bit of a pain to use on the street, and I’ve heard stories of them actually having a hard time with extended durations at light load, like cruising on the highway.

The most common swaps for these cars are Tremec 5 or 6 speeds. The 5-speed come in the TKO500 and 600 flavor (the number representative of their steady-state torque limits) and the six speed is the T56 Magnum, good for ~700.

An advantage of the T56 is you get 5 well spaced gears and a good cruising overdrive. If you want your car to stay in a narrow rpm range from 50 to 150mph, you want a 6 speed. With the 5 speed you get 1-4 similar to the 6-speed, but you have to choose whether you want your fifth gear to be like a T56’s fifth – maintaining good acceleration on a racetrack, but a bit buzzier on the highway (.82) – or more the like the T56’s 6th, where acceleration on track would be feeble, but you get a more relaxed cruise (.64).

For its superior strength and flexibility across speeds the 6-speed can’t be beat. The cost isn’t that much more either, only a few hundred bucks more than a TKO600.

There are some downsides though. First, is it’s a physically much larger transmission than the 5-speeds, which themselves are already a fair bit bigger than the 4-speed Muncies. While the TKOs can fit these old Camaros without tunnel mods, the same isn’t really the case for the T56. The other, is they’re heavy – over 130 pounds.

Long story coming to an end, I went with a TKO600. I don’t plan on acceleration above 4th gear speeds to be something I need to worry about (just don’t want to go that fast in this old thing) – and the fitment and weight benefits sealed the deal.

My motor is nowhere near 500 ft-lbs. of torque even after its planned upgrades so the TKO500 would have been fine, but the 600 was only a little bit more and should provide some future-proofing if things escalate in the future.

That paper has my notes on weight:

Stock M21 Muncie: 70lbs.

TKO600 with shifter assembly: 101lbs.

Hurst shifter assembly for Muncie: 8lbs.

So, in a heads-up comparison, the TKO is 23 lbs. heavier than the Muncie. The TKO installation kit comes with a new crossmember for mounting in the car which saves a couple pounds, for a net +21.

Last bit in this space are a new flywheel/clutch/pp. Flywheel is an aluminum Fidanza, clutch kit is a McLeod RST street twin disc. The clutch is rated to 800hp (future-proofing again!) but by virtue of being twin-disc, retains a lightweight and smooth, streetable engagement. The cost is the clutch assembly is heavy! Every pound the light flywheel saved over the OE iron piece, the clutch takes back. Oh well, at least no net gain there.

Looking forward to eliminating the biggest leak on the car, and taking the revs down to a reasonable place on the freeway. Lots more to do though!

Event 3 (and 4,5) – fizzle

By this time had planned to have completed 3 more events in the Camaro – Porsche Club of America (PCA) autocross May 26, then the “Spring Nationals” ProSolo and National Tour in Lincoln, NE over Memorial Day weekend. Unfortunately, didn’t make any of them.

Plan was to run the PCA event just to make the car was sorted enough to justify the (very long) journey to Nebraska – over 1600 miles each way from San Diego. Unfortunately, some events at work conspired to necessitate canceling the Nebraska trip.

Then the PCA event was a bust too. All the tuning plans from after ProSolo were completed -the new rear brakes were installed (bonus of an even firmer brake pedal), the front shocks were re-valved and reinstalled, and a new ignition system was installed. Also did an oil and filter change (what a mess!) and lowered the rear ride height 1/2″, and adjusted pinion angle further down (to provide a little more pinion yoke <-> driveshaft tunnel clearance).

Unfortunately the ignition part didn’t happen until the day before the PCA event, and was done somewhat hurriedly. Still, the car fired up the first time, and it seemed healthy as ever. The Mallory stuff was all jettisoned for new Crane Cams gear. Plan was to get it through tech, then use some of the otherwise unoccupied time during the day, to button up the wiring.

Got up to El Toro, and the car fired right up on the trailer – pulled it off, and while warming up, adjusted the numbers for the event. Took off through the paddock to get to tech…car feels wonderful, crisper than ever…and … it dies halfway there. Won’t restart.

Some helpful guys help me get it pushed back to my paddock spot, and work commences. Unfortunately the time to get through tech has just expired, so the chances of getting to run are pretty much toast.

Work on things for a bit – I’m convinced it’s something in the ignition, but am not sure what. Try re-wiring all kinds of things, supplying separate power, setting the timing all over…nothing.

Eventually I give up, and the same helpful folks, help me get it pushed on the trailer. It’s a shame the most common question these days isn’t about the engine or suspension, but instead “where should we put our hands to push?”.

Car sat for a while, but had a chance to take a fresh look at it today. Pulled the distributor cap, and as it came off, could hear the sounds of metal bits tinkling down onto the trailer floor. Hmm.

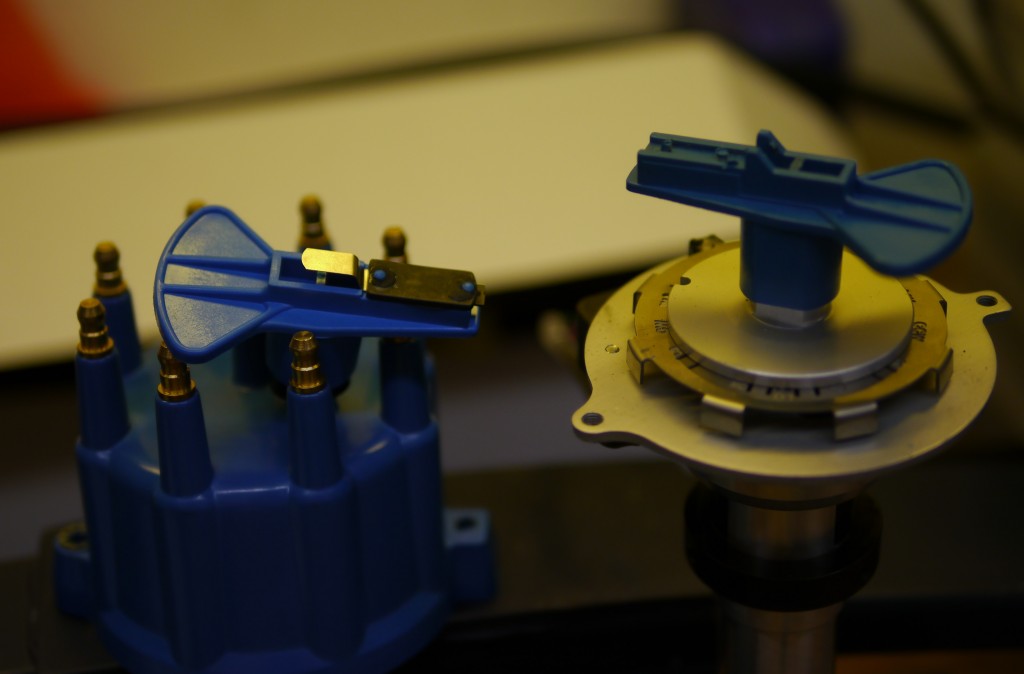

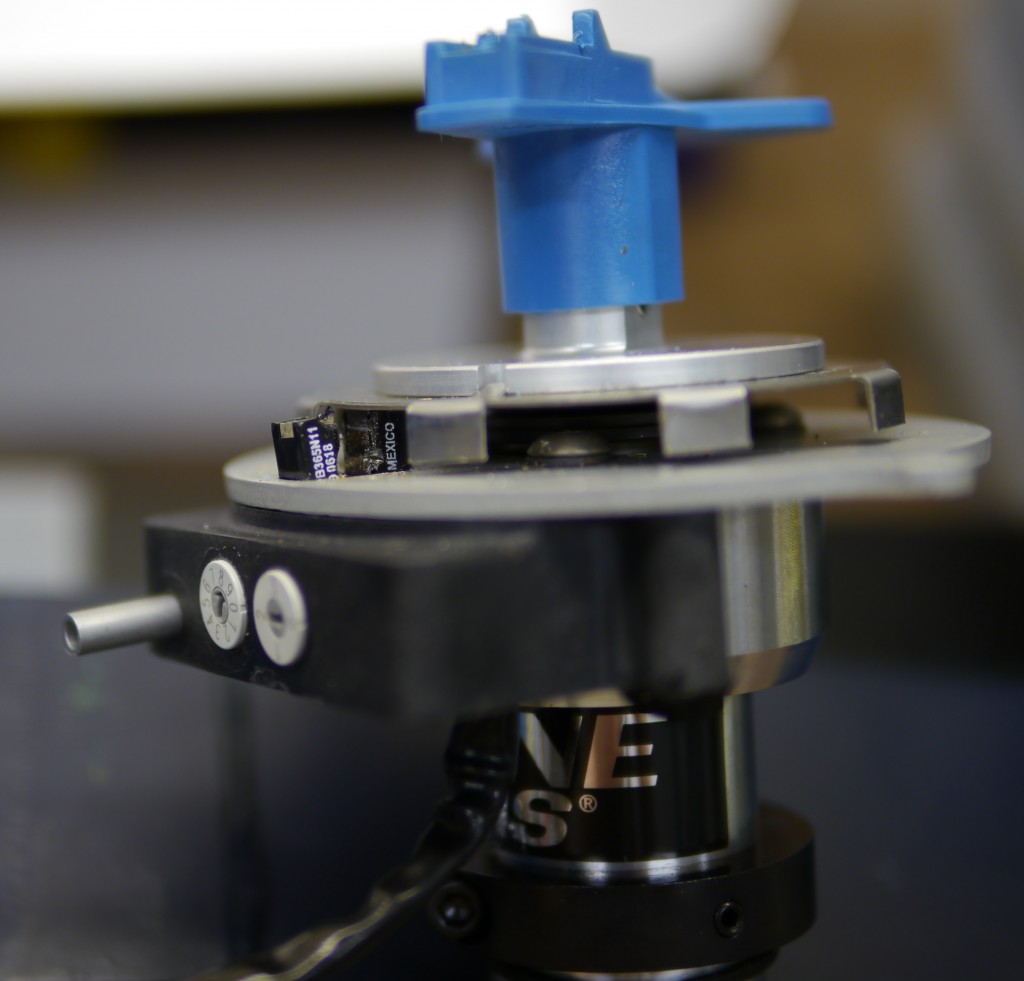

Pull the whole distributor out since it’s hard to see back there, and find the above piece wedged in the optical pickup.

The below picture tells the tale – on the left is a brand-new rotor I’d bought for a future tune-up; on the right is the rotor as it sits.

Notice the metal tang is gone, as is the piece that holds it down. The replacement rotor is of a slightly different design, perhaps other people had this issue with this design rotor.

The first picture above is the center tang’s remnant, after I pulled it out from being wedged in the optics. Optics, which are now toast:

Just bizarre how much bad luck I’ve been having in the ignition department. The cap was on tight and looked fine, not sure how this could have been due to an installation error.

- Mallory distributor #1 – fine for startup and initial street driving, died after 5 runs at SD Tour.

- Mallory distributor #2 – fine for startup, shorted itself out at first run of ET ProSolo

- GM HEI ignition – just *barely* doesn’t fit

- Parts store standard-issue points system – reliable, but car feels down 150hp, and won’t rev over about 5000rpm (day 2 of ET ProSolo)

- Crane Cams distributor #1 – started car fine 2-3 times, until rotor self destructed and ate the sensitive electronics

Next distributor is another Crane Cams piece, the same unit they use in NASCAR. Those cars don’t fail that often due to ignition problems from what I’ve seen…hopefully it proves more reliable, and I’ll always be traveling with at least one spare.

Very bummed I wasn’t able to run the PCA event – first event, the car was a complete handling disaster, second event the car barely ran and the handling was still way off – the handling should be much better now, if I can get it to run reliably 🙂

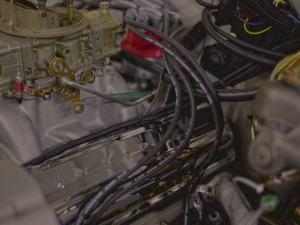

Spark plug wires complete

Not the most exciting thing but did get the spark plug wires all put together – cut to custom length with proper terminal ends.

Running out of reasons to not at least take it around the block 🙂

First idle

Last night I couldn’t really let the car run since it was so late.

Had a few minutes tonight, was able to get the distributor clocked to a more idle-friendly position and re-fire.

With my little helper, was able to get the car idling halfway decent, and later took a video of it running

Will have to wait to the weekend to get base timing set. So far it looks good, no leaks!

Bringing a little CP to STX 🙂

It runs!

Spent every spare moment I had today on this thing, and at last, it runs!

Much of today’s work was in mounting and wiring the ignition coil, which we are allowed to replace in ST.

Since the car is heater delete, the heater blanking panel makes a nice convenient spot for mounting both the coil and the Moroso catch can, without making any new holes in the firewall – which after 45 46 years, has seen a bit of tinkering.

Stock/ST also allow for catch cans, so long as factory PCV/emissions functionality is retained. In this case, the “input” to the can is from the PCV valve, while the “output” goes to the vacuum port on the carburetor. For those not familiar with catch cans, the idea is to have something that captures the misty oil vapors that escape a PCV system under load, and separate out the oil from the air. Any oil consumed by the engine will combust, but it does so at a lower temperature than gasoline, and can lead to detonation/preignition. This is bad on a normal engine, even worse on a high compression engine like this 302, and extremely bad on a forced-induction car.

With the catch an in place, the oily mist is turned into regular oil, which can be emptied out when needed. The engine continues to enjoy a functional PCV system, but through it, only ingests clean air.

The remainder of the work was spent under the dash, getting the DL1 and DASH2 all wired up and talking. Still figuring out the exact song-and-dance needed to get the DASH and DL1 to talk properly, was able to get what I wanted after some effort, but there is probably an easier way.

With the plugs out, verified the motor made oil pressure just using the starter, and that the sender/dash combo reflected the pressure. Still haven’t wired in the fuel gauge or coolant temp sensors, hence their bogus readings.

Later, put the plugs in and ran the spark plug wires. The MSD wires I have are all wrong, will need to get different ones, and route them more carefully. But at 9:09PM, it started and ran! Since the 20 month old was just getting to sleep I shut it off right away.

Still lots to do, but this was a gratifying step, and I met my goal to “have it running by New Year’s” – even if it was New Year’s day. 🙂

Many obstacles overcome, still more to go.

About a month ago I posted a list of stuck-points on the project – fortunately since then, with a lot of effort and tool purchases, progress has been made! Have put more time into the car this past month, than in any month so far. First, an update on each of the old sticking points-

Power steering leakage

New pump was purchased and super-carefully installed. All lines cinched up, and no leaks after a couple weeks, yay! Still have to see how it holds up under the pressure of real use with the pump cranking away, but so far so good.

Brake line fitting leakage

This was due to an incorrect flex line in the rear – correct part ordered and installed, and the brakes were bled, no leaks! My brake bleeding assistant, who’s never driven a manual car, had some trouble with my instructions to “push the pedal in the middle” – since the throttle pedal was sunken to the floor, the clutch appeared in the middle of the e-brake, clutch, and brake pedals. I’m going from corner to corner, wondering why fluid is barely eking out as I hear her pumping away! 🙂 A little revised instruction and it’s good to go.

Still had some air after a couple passes, at which point I realized the multi-piston Wilwoods need to be bled at the top of both caliper halves (inner and outer) to get all the air out. Last few bubbles gone and the brake pedal feels very firm inside.

Leaf Springs

This was a rather labor intensive process. In typical easier-said-than-done fashion they were cut down 2.25″ in length; bushings were trimmed or hogged out to fit appropriate sleeves for mount bolts; the front spring eyes were flipped and ground for clearance; initially the rears were flipped also but it looked like clearance would be an even bigger problem, so they were left upright, but still got some grinding.

This has an ultra-scientific “one to two finger gap” in the rear. Added about 65 lbs. of fuel (more on that later) which only brought it down about 1/8″. Only weight left to go in is the headliner and door glass, so this is where it’ll be for now. It’s not likely this spring rate will be the one I wish to keep forever, so for the next pair of springs, it should be easy enough to request an additional ride height decrease, in addition to the spring length decrease. Bushing work will swap over.

Oh, and in the picture above, the rear wheel has 3/4″ of spacer. There’s room to go inboard or outboard bit if needed, but this provided a more athletic appearing stance, while still providing for tons of wheelwell clearance in all directions. At this setting rear track width is 70.75″, which still, isn’t *that* wide. It’s about 4″ wider than my 240sx was, and about 7″ narrower than the Viper.

Road Draft Tube

Have to thank my buddy John Coffey for talking me through this one. Tried several different things and took a long time with this, and ultimately found a solution. This item was holding up permanent installation for a lot of simple things in the engine bay, so once it was out of the way a lots fell quickly into place – carburetor, fuel lines, distributor, throttle and choke linkages, etc. The tube coming off the road draft vent hole is the black one fuzzily visible in the passenger side carb photo below-

You may note, the stock-style valve covers. These are actually the third set of valve covers I have for this thing – the first set didn’t fit the bolt pattern (they’re for an even older small block) and the second set were a bit bigger and made of thicker material. They *look* nice and original, but caused all kinds of interference problems with things like the fuel line and the bracket for the power brake booster vacuum line, visible above. While in general I’m not a fan of extra chrome, these are at least very lightweight, and totally stock.

Coolant Temp Sensor Port

This problem begat a bevy of tool purchases. After nothing could convince the old plug to come out, began drilling with ever-larger holes. The largest thing I had on hand for going through metal was 3/8″ (bits and chucks), so it was time for some upgraded hardware. Now have a new 1/2″ chuck drill, and an array of drill bits up to 1″ in size.

Also bought a 1/2″ NPT tap to repair the threads, and a special 45/64″ bit as the final pass before using the tap. After using the 45/64″ bit, all that was left of the plug was like foil and I could pull it out with needle-nose pliers.

Hooray! Coolant temp sensor in its appropriate location!

Also visible in this pic, is the new oil pressure sensor. This is a 1/8″ NPT sensor occupying a small port in the block previously filled with a small square plug. This too necessitated some tool purchases since it was a 7mm square plug, so none of my 6-point sockets would fit it, and the only way to fit a wrench on it, would be to pull off the water pump; no thanks. Ended up buying one of these universal socket things, advertised to work on 1/4″ – 3/4″ bolt heads of all shapes and sizes. After some monkeying, it got a grip on the thing and got it out. The tool earned its keep in that one action!

Perhaps apparent from the way the wires for the oil pressure sensor have been run, am making a big effort to keep the wiring tidy and professional in the car. Bought a ton of heat shrink tubing and overlay sheathing, in an attempt to keep everything clean, bundled, and protected.

Vent Windows

No progress on here from last time. The passenger vent window is just about ready to go in, been focused on what’s needed to get it running.

New Progress

Lots of other progress has been made in addition to getting the above accomplished.

First Fuel Purchase

One of the simpler ones – the fuel line installation was completed, so it made sense to get some gas. We happen to have a very neat retro gas station just a few miles from the house, that sells all sorts of good gas right at the pump, and comes complete with a smiling young man offering to clean your windows or check your oil. It’s mostly frequented by the well-to-do’ers of RSF, topping off their Range Rovers and exotic sports cars. I felt out of place with two crummy 5 gallon plastic jugs in the pickup, but the Camaro will look right at home there.

Oh, and this is the only station I’ve bought gas in, in the last 10 years, where you don’t have to pre-pay. Got a lucky click-off of the pump, no coins! Hopefully a sign of good ProSolo reaction times to come. 🙂

Windshield Wipers

This is another that seems like a no-brainer…which of course wasn’t.

Had the body shop install the wiper motor and attach to the wiper arms at the body shop, as doing so requires having the cowl panel off, and installation or removal of a body panel, is a big opportunity to scratch up the paint on said panel.

Unfortunately the wiper arms were not “clocked” to the motor correctly, causing the wiper blade to want to swing down initially, instead of up. So off came the cowl panel, some time spent futzing with the mechanism orientation, but ultimately, the wipers made it in, and I managed to get the cowl back on without messing anything up too badly.

The car had no wipers when I got it, now it has working ones, ha!

Pedals and Header-back Exhaust

The car has four functional pedals at last! Well, the gas pedal may not make it go yet, but it does open the throttle, now that the road draft tube shenanigans were handled.

Brakes were made ok with the bleeding a little while back, and the clutch was okay, as the pressure plate provides most of the springing, but the complementary clutch return spring that keeps the pedal up against the stop, has also been installed.

The parking brake pedal was the last to be made functional. The Wilwood rear disc brake setup on the car has a complete functional parking brake, but comes without a means of adapting it to the factory cable system. Fortunately the solution was pretty simple, with a pair of Lokar “Explorer style” clevises, drilled out to accept the factory parking brake cable. The entire parking brake system is not entirely new, from the rubber of the pedal pad, to the drum lining at each rear wheel.

As you can tell from the second picture, at this point, the exhaust ends at the mufflers. When I get the car to an exhaust shop, will have to see what can be done to extend the exit either to the traditional location, or out the sides. The panhard rod in the rear suspension complicates things.

Ride Heights

They still aren’t right. Rear is too high, as discussed above. I’ve raised the front “2 turns” (haven’t done the math to figure how that equates to inches), but it probably needs to come up more.

This picture was taken a few days ago, before fuel and coolant were added, so both front and rear have since come down a little bit.

You’d think moving the car around a garage floor on dollies like this would be easy – nope, big effort required!

Before trying to drive it anywhere, I’ll probably raise the front another 2 turns.

The Vintage mags with 27+” tall tires will fill the wheelwells better than the Jongbloeds and AD08 rubber. The shorter /35 series front tire vs. the /40 series on the rear, exaggerates the ride height difference.

No problem turning to full lock, even at this ride height-

Pic inside of the front suspension with the wheel turned- contact point at extreme bump, is the lower control arm to the factory bump stop bracket, welded on the frame. At this ride height, it has about 1.25-1.5″ of travel there, equating to about 2″ of travel out at the tire.

Oh, and a funny one-

The family car had to go in for service (Infiniti is paranoid after the Toyota/Lexus unintended acceleration debacle, and is issuing recalls on the new JX35 like crazy. The car needed 5 recalls done, which necessitated an overnight stay) – and since they were busy and out of branded loaners, we got a crummy rental – the Chevy Sonic. The Sonic is one of these economical small cars – not micro like the Smart or Scion IQ, but subcompact like the Toyota Yaris, Mazda 2, or Honda Fit. When my Tundra was serviced I got a Yaris SE loaner, which was actually decent, but this Sonic LT was crap! Anyway, it got to park next to the Camaro one night.

What amazed me was how TALL the Sonic is! Check out this picture-

It only looks a few inches taller than the Camaro…until we see the Camaro is sitting on 5″ tall dollies! Will have to measure the Camaro once it’s back on the ground, but I’m pretty sure its roofline is around 48″, the Sonic (and lots of other cars like it) have rooflines about 60″. Wow.

Battery

Ok, so I put it in the trunk, not very exciting. This is an Odyessy PC680, common in the aftermarket. It’s 13-14lbs., vs the 35+ of the stock battery, hanging way out past the nose. Here’s it’s mounted fairly high, but more or less at the rear axle centerline.

Have more thoughts on general battery placement, will have to share another time.

This battery was bought to get the car going (figuratively, not literally) – since in the beginning it is likely to get cranked a lot without much chance to charge normally, and this should stand up ok to that use. The *real* battery I plan on using is the C680 XS Power battery, which is only about 4 lbs., and is the same form factor as the PC680, meaning it will fit in that mount.

Interior

The insides of the car received some attention, mostly in the instrumentation area.

Steering was a bit out of whack, had to purchase a puller to get it all apart and re-clocked correctly, but it could at least be buttoned up-

The wrap will come off soon! Still getting my hands dirty doing stuff, just not as bad as before.

Note the cover plate over the center of the dash – bare as a no-option car can be.

Couple other things to see – the switch at bottom left, and of course the DASH2 dash. The switch will be an independent control of power for the DL1 and DASH2. The idea is, I can keep it on, to help let the DL1 keep GPS lock between runs, or any other time I want to have the engine off but instrumentation on. Modern cars tend to have as their key positions, Off -> Accessory -> Ignition -> Run. This car has Off -> Accessory + Ignition -> Run. Want to be able to keep some of the electronics going, without all of it going.

Speaking of the DL1, it got its own custom bracket, just below the dash, to the right of the steering column.

That silly bracket took a ton of time to measure and bend up, and I’m still not totally happy with how it ended up, as I had to change its position slightly to avoid having to use a serial extender between the DASH2 and the DL1.

With this configuration, the DL1 will be recording information from sensors (like coolant temp, RPM, and oil pressure) in addition to the things it can figure out on its own – speed and accelerations – and present this data to the DASH2, as configured, over an RS232 serial connection. This is handy, because you can’t really look at gauges while autocrossing. You might have a chance to look at the tach when doing an initial 1-2 shift, but that’s about it really. On the track you can take a glance for a second or so while on a straightaway, to ensure systems are still healthy, possibly even changing your approach if you see oil temps climbing, or something like that. In autocross you go out and hope the car makes it through the run without self-destructing. If you are having momentary drops of oil pressure, there’s no way you’ll see it, without some kind of alarm light programmed in, but that can be tricky, since 20psi might be OK at idle but death at 6k RPM. With the data acquisition, you’re watching the gauges 100 times per second, and if there are any concerning fluctuations, they can be correlated to other events, like hard right-handers following a braking zone, for instance.

In this photo it isn’t yet talking to the DL1, so it only knows to output fuel level, which it will get from the main vehicle harness, and will not be datalogged. Common Camaro Lore dictates one most always autocross a first or second gen Camaro with a completely full gas tank. I’m hoping that’s not actually the case, will find out soon enough.

The DASH2 is mounted to the steering column via a custom bracket I made. When I envisioned the bracket, it had to be carbon fiber, and making it so, took extra time. In trying to get a photo of it tonight, I now realize now silly that probably was, you can only really see it when looking down through the windshield. Here it is, from roughly the middle of the car up against the windshield, looking back and left-

Even if the aesthetics aren’t perfect, pretty happy with how it turned out functionally. The size and positioning of the bracket and DASH2 unit, allow the wheel its full range of tilt adjustment, without bind or interference. Here it is fully tilted up-

With the steering wheel in a normal position, eye level is slightly above the unit, which is supposed to be optimal for its viewing.

Race-Technology was very supportive in sending me out a loaner so I could get the car fired up, while they send my bricked unit back to the UK for repairs. Thanks Al Seim and R-T USA!

Belts

Not very exciting, was able to get a good length PS belt on the second try, looks like I’ll need a third attempt to get an alternator/fan belt of the right length, this one is a bit too long-

Looks like I may need to spend some time shimming the PS and water pump pulleys to get perfect alignment. Like so many things, you think belts will be a 5 minute deal, and it turns into hours… 🙂

###

The plan for the moment is to get it running, and solid enough to not fall apart or puke its fluids out everywhere on a short drive. Want to make sure it builds oil pressure by free-cranking it with the plugs out, before they go in and I try to fire it. It *should* be fine as it ran great on the engine dyno, but that was over 2 years ago, and it has since received a new oil pan.

It’ll need to go to an interior shop to get the headliner put in (it’s a least a 2-person, if not 3-person job on these cars), then to an exhaust shop (have some tweaks to the Magnaflow system I need/want), and to ProParts USA for some shocks. I want to have the car ready for the San Diego National Tour, which is a short three months away!

Some underhood shots

Have made some progress in the powerplant department. Cooling system pretty much fully installed – radiator, hoses, water pump, thermostat. Throttle, brake, and clutch linkages all in place. Still have some work to do with fuel lines, brake lines, PCV stuff, and all the electrical and ignition.

Decided to procure an OE-style air cleaner, just to have something to start with.

Changed lens between shots here. I really enjoyed seeing all the nice photos other people had taken of their cars in the various stages of construction, trying to repay my debt to the car-builder society with my high-res photos in this blog.

Main purpose of this camera is video actually, should have some better-than-GoPro stuff to share, once there is movement and audio to capture.

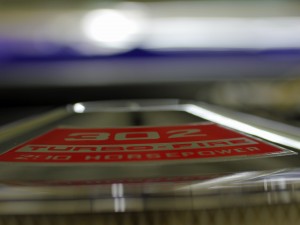

One benefit of running the OE air cleaner, is with the addition of a simple decal, you’re providing a pro-active answer for the dozens of inevitable “What kinda motor you got in there, how much horsepower does it make?” queries

It’s a stock 302 making 290, of course! 😉

Few random pictures – two sets of wheels & engine compartment

Some of the prettier aspects of the car should be coming together soon. These first two are of the Vintage Engineering magnesium wheels, after coming back from receiving their DOW 9 coating.

Ray at Vintage then drills for the Camaro bolt pattern, and removes the coating from the outer lips with a scotch-brite pad on a lathe. When done they look like the other two I’ve already received. When they’re all here, will get the vintage-style Avons mounted up and put on the car.

Those are just for the street and any show-type activities though. The ones below are the real deal race wheels. 18×9″ Jongbloed 214 Aero, with custom backspacing, different front and rear.

Jongbloed mounted up my first set of brand new shaved ST tires on those today, should have them this week. Congrats to Mike Heinitz for correctly identifying the wheel pattern after I showed them in process back here.

Below are a few of the engine compartment, coming together, for real this time! 🙂 The March Performance pulleys look really great – they add a pop of shine without the obnoxiousness of chrome, and don’t betray the simple mostly-stock, all-business look I’m after.

With any luck I’ll have some rollers on this thing for some out-in-the-driveway shots this weekend.

Oil pan

Whew, that was a bear. Too bad ST didn’t allow aftermarket oil pans in 2010 when I had the motor built, or 2011 when I put it in… 😉

An oil pan swap can be done with the engine in the car, but it’s a bit of a pain, have to remove some things, jack it up under the old pan, use block to get it to stay up high, swap pans, and then lower back down.

Was able to get the stock pan off without too much trouble, but the aftermarket pan I ended up using from Milodon, hangs down a bit lower than stock, requiring the motor be raised even further. Underside of the car as it looks today:

This pan has an increased oil capacity from stock (7 quarts vs. 4), left and right-side kick-outs (lots of circle-track stuff out there with only right-side), and three internal trap-door baffles. Here is a photo illustrating the concept (courtesy this Alfa Romeo site):

The principle with these doors, is they all hinge into a small central area where the oil pickup is located. They keep oil from rushing out as g-forces build in braking, cornering, or accelerating, and allow oil from the perimeter reservoirs to push the door open and flow into the pickup area.

Even with as old and simple as this car is, there is still some fairly tight packaging at work. The pan gets very close to the steering, the headers, the monstrous stock starter, has a cutout for an oil filter, and just barely tucks up higher than the stock crossmember, while still being a little deeper than the stock pan.

With all its tricks, the pan should go a long way in helping ensure a steady supply of oil to the pump in big corners. Between the weight of the pan and extra oil there’s probably another 10 pounds on the nose of the car, uggg, but I’ll take it as good insurance. Will probably still run the Accusump accumulator at non-SCCA events for that extra measure of protection.

2 rule changes for 2013 – motor mounts and oil pans

The rules I have linked to here were for the 2011 season, and it’s looking like 2013 will be the first real season the car gets.

The SCCA released its October Fastrack recently, and besides the controversial classing of the new Scion/Subaru FT86 twins in STX, two new allowances were communicated.

One, the ST category is now free to run motor mounts of unrestricted origin, so long as they are no lighter than stock.

Two, the ST category is now allowed to run aftermarket oil pans and pickups.

The oil pan allowance will be a great help to the Camaro, as the car is not known for its good oil control from the factory, under heavy lateral loads. The motor mount allowance is less of a boon, but in theory, having the engine solidly mounted could contribute to overall vehicle stiffness, which is a weak point of the Camaro.

So solid mounts it is. First, I weighed the brand new Prothane mount as a baseline. The original motor mounts were long long gone, so I don’t know exactly what they weighed. The Prothane units are quite beefy, made of solid polyurethane, whereas factory mounts tend to be soft rubber with voids, allowing for more movement. I figure as long as my solid mounts weigh at least as much as the Prothane mounts, I’ll be ok. If anyone out there has a perfect OEM motor mount they can weigh, I’d appreciate it.

Here’s the Prothane, not light at over 35 ounces:

And here’s a new Moroso solid mount:

12.4 ounces, almost 23 ounces lighter, so between the two, almost 3 pounds difference! Ugg. Going to have to figure out how to add 3 pounds to these mounts to stay legal.

The oil pan is another project, haven’t quite started on yet.