Front suspension continued

A while back I left off a post with this picture:

The angle, a bit over 8 degrees (90-81.7=8.3) is the “kingpin inclination” (KPI) or “steering axis inclination” (SAI) angle. It is basically, the angle from vertical about which the knuckle rotates when steered.

There are pros and cons to this angle being big or small. One pro, is it ends to reduce the “scrub radius” that some people say is a bad thing. It also provides a centering force akin to positive caster.

A con though, is that it produces positive camber in the outside wheel – i.e., if you turn right, the left front wheel will get positive camber just from turning. The higher the KPI, the more positive goes the camber. This is a Bad Thing.

Can’t change KPI in this class, really requires a whole new knuckle. But we can fight this Bad Thing with a Good Thing, and in our case that Good Thing is positive caster.

Caster is the same sort of angle as above, except as viewed from the side. Positive caster produces negative camber on the outside wheel when turned. The more positive the caster, the more negative camber gain.

Autocross has some fairly tight maneuvers, ones that often require large amounts of steering angle input. Long wheelbase cars like the Camaro have to use even more steering input around given radius corners (see CVD 4 – Skidpad for some explanation), making it all the more important that, to the maximum extent of our rules-bound ability, we minimize any unfavorable consequences of turning the wheel.

Many modern cars use a lot of caster. The Porsche 911 GT3 uses upwards of 8.5 degrees; some Mercedes-Benz come from the factory with over 11 degrees. Heck, even the latest Mustang uses 7 or more. Lots of sporty cars made in the last 20-30 years provide 5-7 degrees.

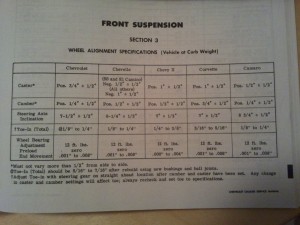

Most people don’t believe me when I tell them what the Camaro’s base caster setting is. Here’s photographic proof, from my Chevrolet Chassis Service Manual, (far right column):

That’s right, the factory caster setting is positive 1/2 degree, plus-or-minus 1/2 degree. Meaning potentially zero degrees positive caster! So with over 8 degrees of KPI/SAI, there is almost no positive caster to counteract that positive camber gain on the outside front tire.

Just another facet of how bad the first-gen Camaro’s front suspension is from the factory. 🙂

So, to try to nullify this Bad Thing we’ll add some positive caster to the equation. Common thinking amongst most of the first-gen Camaro guys is that “4 or 5 degrees is enough”…which of course means that I’ll be aiming for at least twice that much! 🙂 The thing is, even at about 8.5 degrees of positive caster, its beneficial effects are only canceling out the detrimental effects from the KPI. A first-gen Camaro with 12 degrees of positive caster will only see about the same positive effect from caster, that a “normal” car would get with 6-7 degrees.

Adding all this caster isn’t a trivial endeavor either. There’s a few side effects that must be managed.

One is an increase in steering effort. I’m a big believer in providing the driver with a stable, precise, sensitive, and consistent platform upon which to operate. If we require the driver to use big muscles to dance the car through the course, we can’t expect the driver to have a lot of precision touch in his inputs. To help enable this, I plan to run power steering. An excellent race seat will hold the driver in, without any stabilizing forces through the wheel. This should enable “fingertip” steering wheel forces, enabling the driver to maintain a much better feel for the front tires. I believe the power steering ratio on the Z28 was also a bit quicker, which I like – it’s also harder to be precise when you have to produce huge turns of the wheel in a small amount of time.

The other side effect is it can change your wheelbase. The traditional (and FSM-specified) way of adjusting camber and caster on these cars is to use shims on the upper control arm’s inner attachment point. Use of shims at both ends produces negative camber, and their use at one end or the other changes caster. The threaded upper bolts are long enough to produce large amounts of change. This method of caster adjustment moves the upper ball joint “back”, and if the hub is centered between the upper and lower ball joints, moves the wheel centerline back half that distance.

The problem here, is the whole wheel is moved back in the wheelwell, and with the amount of caster I plan to add, doing it all with the upper arm, would move the wheel back more than 1/2″. I want to be able to run very very low, and do everything I can to reduce or eliminate rubbing with the big 265-section front tire. The Camaro’s inner fender has the most vertical room right at the stock front wheel centerline, which means I need to keep the wheel centered to maximize how low I can go.

To keep the wheel centered, but still produce large caster values, means I need to also move the lower ball joint forward, while moving the upper ball joint rearward. If I move each equal amounts, the wheel stays centered in the wheelwell, and I get to enjoy the yummy KPI-canceling positive caster.

Since I’m spending my custom control arm allowance on replacement upper control arms, I have to stick with the stock lower arms. However, there is an allowance for replacement offset bushings. So long as these offset bushings don’t contain any more metal than stock, I can use them to produce some of this same caster gain. You can see in the pic below, how the mount axis goes through the bushing cylinders at an angle – this produces a clockwise rotation (in top view) of the driver’s side lower control arm, moving the lower ball joint forward.

John is just about completed with these custom Hydlar lower control arm offset bushings for the Camaro. There’s a good amount of “meat” to the stock bushings, allowing for a satisfying amount of longitudinal forward offset of the lower ball joint. It probably isn’t enough to produce entirely half of the caster I’m after, but it’ll be close, and should make a big difference in keeping the front wheels centered in the wheelwell.

A lot of the first-gen guys add a bunch of positive caster to their cars all with the upper arm, and run into bad rubbing problems, because of this rearward movement.

Anyway, these offset bushings are a relatively small detail. The thing many people overlook, is lots of small details start to add up. An ounce of weight savings here, a smidge of improved alignment there, maybe another 1/2 hp freed up, all make a difference. Those who remember their Calculus know, that even when you’re dealing with really really tiny quantities, so long as you find enough of them to add up, you can eventually end up with a substantial (Riemann ;)) sum.

This “sum of many tiny parts” thing was made most clear to me not in Calc class, but at the 2005 Solo National Championships, where I was codriving with Gary Thomason in his insane SM2 C5 Corvette. Anybody who knows Gary knows how meticulous he is in the care of his cars – not just their finish and appearance, but in their overall state of tune and function. Gary was constantly tweaking things with the car – 1/32″ rear toe changes between runs, fraction of a PSI difference in the tires, etc. I’ll never forget the morning of day 2, him looking to find a way to get the running lamps to stay off.

The car’s AFR-headed LS-based 408 was making 600+hp, but the real story was the insane low-end torque, combined with the stock short Z06 gearing. The thing would obliterate the tires with a hair’s too much throttle. It took a perfect alignment of the planets before you’d even consider full throttle, and on most courses you never got there. Yet here we were, out on the beat up old airbase at Forbes Field, trying to get the running lamps to stay off, which would reduce the load on the alternator and free up some tiny bit of HP.

We found a way to keep them off, and on his last run that day Gary blazed an unbelievably fast time to pull ahead of Andy McKee in his superior RX7, and take the championship. While obviously you need the Big Stuff like top driving skill and the right tires in place to be contending for a National Championship, I now know that what many perceived as alien ability, or good luck on an unusually fast run, was actually the synchronous coming together of an uncountable number of tiny, carefully orchestrated, details… including that ‘Vette’s last 1/3 of a horsepower.

Rear axle lateral locator complete

So you’d think with nearly complete freedom to design and implement a top-notch lateral locating device for this live axle car, one would choose a Watts link right? After all, a Watts offers perfect symmetry when turning left and right, and doesn’t move the axle laterally as the suspension moves through its range of travel.

Along those lines, the first big question for anybody implementing a Watts link, is whether to make the main pivot point chassis mounted, or axle mounted. Axle mounted (image courtesy Griggs Racing):

Chassis mounted (image courtesy Fays2):

There’s a couple imperfections with the Watts however. The first pertains to the above choice. If you choose the axle-mounted center pivot, then you get the “advantage” of a consistent roll center height. But half the world will tell you you’re an idiot, because the sprung mass of the car moves in squat and pitch, so the “lever arm” from the roll center to the center of gravity, changes during squat and pitch, dynamically altering the rear roll couple. Plus it’s harder to adjust.

So you can instead choose the chassis-mounted pivot. This keeps the roll couple more consistent as the car pitches and squats. But now you’ve got to build a big heavy structure to support the center pivot, plus…wait a second, maybe the roll couple changes from the diff-mounted center pivot (loose on entry, tight on exit) could be beneficial? By now the other half of the world thinks you’re an idiot for having done a chassis-mount Watts.

We won’t even talk about a Mumford link, which might be cool if you’re scratch designing a live-axle chassis, but on something like the Camaro it would take 40+lbs. of structure welded into the rear to support it.

In keeping with the style of a person building a 44 year old car for a Street Touring class, I’ve made the choice that lets everybody (not just half) think I’m an idiot – a panhard rod.

Now, we all know the downside of the panhard – it moves the axle laterally as the suspension moves. The shorter the panhard, the more movement. The panhard bar on the car now is about 34″ long, which is as long as it could be made when considering the packaging restraints of the leaf springs. Another mitigating factor is, as with the front, by keeping the rear suspension stiff, I’ll be able to minimize the vertical (and thus lateral) movement of the rear axle. At 2″ of travel (pretty much all it will get), the axle will shift laterally by only .06″, about 1/16″. This is not a completely negligible amount, but I plan to run tall-ish sidewall rear tires, which will mask much of this, and we see tires move around on their wheels by 1/2″ or more while under heavy load.

The other maligned characteristic of a panhard rods vs. Watts, is their asymmetry in handling. The roll center, usually defined as the bar’s midpoint, rises or falls based on which way you’re turning, and which way you have it mounted. This will always create a difference in the way the car behaves turning left vs. right. Even if you start with the bar horizontal at resting height, as the car rolls, the lateral forces fed through the now-non-horizontal bar will serve to load the rear axle differently depending on which way you turn.

On the surface this may seem like a bad thing, but it can be used to counteract other asymmetries. For instance, in a live axle rear car, on hard acceleration, driveshaft torque is going to tend to weight the driver’s rear tire, and unload the passenger rear tire – that’s why you always see drag racers mounting their battery in the right rear, and why live-axle cars usually have such a bad time putting down power out of right-hand turns. This car is going to be making good power with good gearing so when good grip is available, this asymmetrical loading can become very significant.

We can use the panhard to counteract this asymmetry somewhat, by mounting it to the left half of the axle, and to the chassis on the right. This puts the panhard in compression, when in a right-hand corner. That compression is going to help better load the rear axle in right-hand turns, counteracting some of the axle’s natural asymmetry.

And actually, there’s a lot that’s asymmetrical about any race track, and any Solo2 course – both are either clockwise or counter-clockwise (ProSolo, with its mirrored courses, is the exception). The panhard rod is unique in that it allows one to adjust-in some inherent asymmetry, that may help if a particular event features a strong abundance of key turns in one direction or the other. It’s also lighter and less complex than the other options.

My panhard bar is simple but should be very effective. The sawtooth axle-end adjuster and screw-type chassis-side adjuster supply an essentially infinite number of discrete adjustment postions, as opposed to the 4-5 “holes” most solutions offer.

The solution overall is only about 16 pounds, a good bit lighter than the Watts options I’ve seen out there. Only about 6 pounds of it is unsprung weight, and the axle-side mount (all unsprung) will be lightened a bit – it’s designed to be bolt-on to the axle, but by welding it on, can eliminate the weight of the bolts and some other unneeded structure, while actually making it stronger.

The rear suspension still isn’t done from a fabrication perspective, though it’s getting close. Where’s my rear sway bar? Still that to do, soon thereafter should see some progress on the front. There’s one or two goodies visible in the pics above, I’ll let people chew on them for a while before discussing them further…

Subframe connectors completed

Well these puppies are finally done! Not content with the method of attachment as provided, I had John modify them to add a third attachment point, about halfway down their length. John found a place that would work on the chassis, then drilled a hole and welded in a tube to hold the bolt:

Since the connectors don’t sit flush with the floor of the car at that point, he had to make custom delrin spacers between the car and the connector.

Here they are installed. They look like they’re different heights because they are. Uniformity of 60’s chassis aren’t quite what we see in more modern stuff-

My hope is this additional attachment point, on a different longitudunal axis (the as-delivered front and rear attachment points are in-line longitudinally) will provide a meaningful increase in torsional rigidity above-and-beyond the parts as they came. We can’t do weld in and are allowed 3 attachment points so by golly I’m going to make use of all three!

Every part on the car that doesn’t absolutely have to be there, is going to have to work hard to prove to me it’s worth its cost in pounds. I may do some testing down the road with the connectors removed, to see if, in measured time around a course, I’m getting 24 pounds’ worth of rigidity out of them. If their benefit is not worth their weight in time, off they go. These things are about as good as I think you could make 3-point bolted-in subframe connectors so if they aren’t worth it, nothing I do legally with the allowance would be.

Third attachment point comes through in proximity of rocker and pan reinforcement for seat mounts, should be a good spot to take some loads.

Front connections all snugged up

And the view from front to back.

Another benefit they should provide a good safe place to jack up the car from the side. The traditional front crossmember jack point will be inaccessible at the ride height I’m likely to end up with, especially since it looks now like we’ll be able to use factory-only spoilers – a rule change which happens to suit me PERFECTLY, as I’d only ever wanted to run the factory front air dam and rear lip spoiler. I don’t know if I’ll be able to use the traditional under-diff jack point in the rear either, once all the workings of the rear suspension are together. These things may end up providing the only good place to jack up the car. So hmmm, maybe I will have to keep them regardless…driving a car up ramps just to get a jack underneath is a tremendous pain – been there, done that.

Little more fab – leaf spring shackles

John made some more progress last week on the car. I’m actually very excited about the most recent thing completed – he was able to bring to life in steel, a part I’d only been able to visualize.

What part? Well, let’s just say this car will have the most kick-butt leaf spring shackles ever. 🙂

I don’t quite yet want to show the part, I’d like to wait until the car’s had its underside cleaned and painted so it’s all uniform. This is something of a hint though:

For the next couple weeks John’s been pulled into some other projects to the car’s on his back burner for a bit.

Fab work underway – subframe connectors

Haven’t done much on this project myself over the past 2 weeks. Cleaned the garage which was getting a bit funky from the disassembly phase, despite continuous cleanup. Sometimes old cars are like leaky faucets of dirt and grime. Feels like you could saturate the world’s supply of Simple Green and shop towels, and still you’d be instantly dirty, knocking dirt all over the floor, the instant you touched it. Hopefully by the end of the body/paint phase the car will be to the sanitary state I seek. One thing I have been doing is cleaning up the side glass, to remove 40+ years of gunk and some recent overspray.

So while I’ve been slacking, John Coffey of Beta Motorsports got started on the car this past week, and was kind enough to snap a few photos along the way.

The rear axle was removed and taken to Unitrax, they’ve checked it for straightness and given it a clean bill of health. They’ll be setting it up with the new ring & pinion I located. There’s a nice variety of final drive ratio choices available for the car: http://camaros.org/drivetrain.shtml#AxleCodes

My initially chosen ratio will provide a bit over 66mph at my initially chosen redline, with a rear tire that does 820 revs/mile. There are options to add more top speed in second (besides raising the limiter to unsafe levels), but I think this will be a good start. At Nationals in 2010 I only hit 68-69mph top speed in the Viper, and with its R-comps, the Viper had a higher speed at the apex and could come off the corner harder than the nose-heavy street-tired Camaro will be able to. At Nats 2009 we hit 72, and I did hit 74 and 72 at the SD Tour and El Toro Pro in 2010, so we’ll see. A taller final drive would make it a bit easier to drive, but I’m worried it might chug a bit (by V8 standards) off a really slow corner. At Nats 2010 there were a couple 30mph corners in the Viper, and I’ve seen National-level events with 25-26mph corners. Sure, there’s always first gear, but after having done a bunch of shifting for 3 years in the Viper, I’m looking forward to a more traditional second-gear-everywhere approach in this car. Not having ABS is going to keep my feeble and already-overloaded mind busy enough when braking into a slow corner.

***Along the above lines – I have an extensive process I use in evaluating cars (like the 240sx, Viper, or this thing) for a class, a part of which I’ve skimmed in the paragraph above, and lightly in other posts. If you’re interested in seeing this process more thoroughly described, email me (jason@rhoadescamaro.com) to let me know. It’s going to be a lot of work to explain everything so I don’t want to start on that road unless I know people are interested. I’d do so in a parallel blog as it’s not really Camaro specific. Analysis would broken down into the following seven chapters, which cover everything your car does in an autocross or track lap:

- Straight-line acceleration (which answers the eternal HP vs. TQ question, how to choose gearing, etc.)

- Skidpad (including an explanation of tires to the depth you need to know)

- Transitions/slaloms

- Straight-line braking

- The launch

- Corner entry

- Corner exit

***

A while back I bought a pair of subframe connectors: ( http://www.rhoadescamaro.com/build/?p=263 ) and John set about modifying them. We’re allowed three mounting points:

H. Longitudinal (fore-aft) subframe connectors (“SFCs”) are permitted

with the following restrictions:

1. They must only connect previously unconnected boxed frame rails on unibody vehicles.

2. Each SFC must attach at no more than three points on the uni-

body (e.g. front, rear, and one point in between such as a seat

mount brace or rocker box brace).

3. SFCs must be bolted in place and not welded.

4. No cutting of OE subframes or floorpan stampings is permitted.

Drilling is permitted for mounting bolts only.

5. No cross-car/lateral/triangulated connections directly between the

driver’s side and passenger’s side SFCs are permitted. Connec-

tions to OE components such as tunnel braces or closure panels

via bolts are allowed and count as the third point of attachment.

No alteration to the OE components is permitted.

6. SFCs may not be used to attach other components (including but

not limited to torque arm front mounts or driveshaft loops) and

may serve no other purpose.

But these only have two attachment points, at the very front and rear. If I’m adding 24 pounds of steelitis, I’m going to get every last bit of value out of these boat anchors! John will be adding an intermediate attachment point to bolt them to the rockers, but he needs to get them in position first. Along with that is the installation of the (stock height) replacement subframe bushings. Would probably use aluminum here if the rules allowed, but since they don’t, delrin it is.

So apart come the subframe bushings, last torqued down about 44 years ago by some fellow in Van Nuys, CA:

John cleans things up a bit before proceeding:

And loosely put together with the new bushing-

Similar process for the rearward body mounts:

And together with new bushing and subframe connector-

Need to ensure the subframe is square to the body before anything is tightened down, so out come the plumb bobs:

I suspect it’ll come out of John’s shop with a more accurate subframe alignment than it had when it rolled out of the factory 🙂 It’ll have to come apart again later when it’s time for paint, so John will put some things in place to aid in more rapid future alignments.

Driver side connector initial install, no problems:

Passenger side, BMR, we have a problem:

The passenger side connector has a bit of counterclockwise-when-viewed-from-rear “twist” in it, and the rear backets are not square. This part ain’t goin’ on the car! I imagine BMR will ship me another one to make this right, so it’s not the end of the world. I consider myself lucky to even have a decent part available that’s legal for this ruleset – pretty much every other subframe connector involves cutting the floorpan (you can see how a straight path would require this), and welding things to the car. Who knows, maybe they were doing their website’s photo shoot the day my parts were made, which distracted the welder-

A lesson here for everybody fixing up your car, is to not assume any part you get is correctly made or configured, even if brand new, and even when it comes from a highly regarded vendor.

Phase 2 begin

Couple updates for 11/29. Took the day off work today to get the car up to the aforementioned John Coffey at his shop, Beta Motorsports :

In preparation, thrashed late into the night yesterday putting the back end of the car together enough to get it rolling. Last minute run to the auto parts store for some bearings, and together went the diff.

Here it is floating out in space, just like the stock one that came out. But notice here, the Hyperocoil composite leafs, and the once-horrendously filthy 12-bolt, now cleaned up to only moderately filthy, with fresh wheel studs.

Car sits a “little” high on the springs – should come down a little with time as things settle, not to mention the weight of many components like the fuel tank, trunklid, back seats, etc. Still, I worry I’m going to need to have some custom fiberglass leafs made, as the car is about 4-5″ too high here and with 250lb. springs, should only come down a couple inches with the weight.

This morning, went and rented a trailer. Loading a car with no engine or brakes on a trailer sure can be fun! Ratchet straps make decent winches in a pinch…

Was yet another beautiful day in southern California. Cold, but clear. Took this in honor of the recently passed Leslie Nielsen:

And finally, car made it to Beta Motorsports. I have about a dozen different projects for John, which will take him through most of December. Fine by me, plenty to do on the side while he works. As he completes things, I’ll post pics and explain what was done with each sub-project. John will be fixing a few things wrong with the car, modifying a few of my aftermarket parts to work better, and fabricating a few things from scratch. When he’s done, the chassis and suspension will be “done” from a fab perspective. I still expect to do a lot of suspension tuning, the fruit of this work will be a solid and highly adjustable platform upon which to tune. It’ll also be done from a welding/fab perspective to I can then take the car to get body and paint done.

Why are old Camaros always so slow?

Them be fightin’ words in some circles but since this is my blog, it’s a fair question to ask. The context of the question today, is around why they’re slow in autocross, when seen from the eyes of a typical die-hard SCCA competitor.

One of the more interesting aspects of this project, has been the speculation and conjecture on why the car is going to be slow in STX. As a car builder, one ought to understand their platform, and in leveraging available allowances, do everything possible to minimize the impact of any deficiencies, while accentuating the strengths. We all *know* these Camaros are slow at dodging cones – but what specifically makes them so slow? Some are convinced it’s the axle-tramping rear suspension; others are sure it’s the front suspension, still others think the car won’t really be making good power vs. its competition because of optimistic 60’s SAE Gross vs. today’s Net HP ratings. Or maybe it’s way too big and heavy, maybe the brakes can’t be made to work, maybe the steering is too slow.

Well, I am sure there are many possible reasons, and until I’ve got it running and tuned as well as I think I can, we won’t know which of the above are true. Maybe none of them apply if the car is built right; maybe all of them are true, regardless of all you do (at least within ST rules).

Though I haven’t gotten too far with it yet, there are two Very Big Things I see holding these cars back in the majority of cases, that I’ll address in this post. Hopefully with my advance knowledge of these shortcomings (queue G.I. Joe) and some efforts made in mitigating them, I can overcome. Here they are below, in no particular order-

BIG THING THAT MAKES EVERY AUTOCROSS CAMARO YOU SEE SLOW #1:

The person tuning and driving that Camaro you see, doesn’t know what they’re doing and/or didn’t build their car to “go fast”. Now, I understand that statement comes across as horribly arrogant, but let me explain-

We all (or most guys, at least) tend to think we know what we’re doing the first we get behind the wheel. “Of course I’m an excellent driver”, and we continue to believe it until we see the times of somebody who really is fast.

To use one of my favorite memes in illustration,

| First I was like- |

|

| so I was like, |

|

| but then I was like- |

|

You just don’t tend to see the really fast guys driving old Camaros at SCCA events, and you almost never see the really fast guys at non-SCCA events. They’re often running more modern and closer to stock Miatas or Corvettes, or whatever the hot car is that year. The best drivers tend to flock to the platforms that are believed to be competitive, because they want to win! It’s super rare to see somebody really good (and please, don’t for a second take that to mean I think I am) driving an oddball platform. What this means is the general Good Driver rule still applies to Camaros- a “really good” autocrosser could hop in the driver’s seat of a “beginner/intermediate” Camaro autocrosser, and usually beat them by a few seconds on 50-60 second course. In some ways the non-competitiveness of Camaros, and many other interesting cars, is a self-fulfulling prophecy, as those who own them are likely to get discouraged by their early results and lack of any evidence they’ll ever be competitive, leading them to to not stick with the sport long enough to get any good at it. Who knows, perhaps with some success maybe I can change that – I sure see more Nissan 240sx’s out there today than I saw before 2006.

So there’s the driving element – if the person driving that Camaro wouldn’t be competitive in the Miata or Corvette or whatever, there shouldn’t be any expectation they’ll be fast in the Camaro. Subtract a few seconds for a really great driver, and maybe the car looks a bit less bad?

The other aspect of this relates to tuning and preparing the car to go fast in autocross, and skill in this area almost exactly parallels driving, though most people seem a little more willing to admit their shortcomings in this space.

There is an unbelievable quantity of parts out there for these cars, as they’ve been undergoing speed tweaks for over 44 years now. While as best I can tell the majority of effort into these cars for decades was around drag racing, the idea of making them go fast around corners has become very hot in recent years and the parts variety reflects this. The “handling” renaissance begat a staggering quantity of suspension parts but not a lot of good guidance on what to do with them. Individuality, limitless modification options with no rules boundaries, and differing levels of willingness to sacrifice street manners on the altar of speed, have prevented the crystallization of a “spec” setup for the Camaro. A good example of a spec setup, is that for the super-popular Street-Touring 1989 Civic Si, published by Chris Shenefield about 8 years ago:

http://www.redshiftmotorsports.com/RedShift%20Tech%20Page.htm

With no spec setup to start from and no prior experience assembling a proper-handling autocross car, it’s no mystery so many of these cars end up not working very well, driving aside. The Camaro as a platform is a deep dark hole to climb out of, too difficult to expect anyone to succeed with as their first autocross tuning project. You can put your faith in what your suspension vendors tell you, but their answers are going to be targeted to the middle of their demographic, who may care more (or less) about a comfortable cruising ride, than you do.

There are some people floating around out there in the old-Camaro world who kinda know what they’re doing around the cones, I think, but since there isn’t really any sort of rules in the old-car specific events, it’s impossible to tell who’s doing a lot with a little (bit of modification), or who’s doing less, with a whole lot more. Structure and rules are frowned upon in those circles, which is a shame because it makes results impossible to use in drawing conclusions.

I guess as a message to all my fellow old Camaro owners out there – if you really want to be fast in your Camaro at the autocross (and largely also, the track) – the best thing you could probably do, is park the Camaro for a while. Get a Miata, or an S2000, or a Corvette, and go run a ton of events (SCCA preferably). Figure out who the fast guys are in your region and track your times against theirs. Even better if you get a similar car. By getting a car that’s great out of the box, you can forget about setup and focus on driving. This will teach you the importance of driving, while at the same time familiarizing you with the characteristics of a proper-handling car. When you’re ready, then go back to the Camaro – I suspect the experience gained in a “good” car will better illustrate how far you have to go with your Camaro. It should also help you better understand the importance of different modifications, and get you to spend the next few bucks on tires or shocks, instead of a supercharger.

How am I going to avoid this common problem? By drawing on my experience as a driver and a tuner from many other cars, to dig this thing out of the deep dark hole it starts out in. I don’t have any success stories to look to, but that’s part of the fun/challenge.

BIG THING THAT MAKES EVERY AUTOCROSS CAMARO YOU SEE SLOW #2:

The stock front suspension really is as bad as you’ve heard. There’s a lot of things wrong; below I’ll attempt to explain just one facet of the wrong-ness 🙂

Most of the old Camaros you see at the autocross look awful – they are too soft, and the front suspension looks like it’s doing the opposite of what it should.

Not trying to pick on this car or driver here – this photo pulled from http://www.milesspeed.com/ – a neat site I stumbled across in researching these cars. Car is owned/driven by cool chick Liz Miles, and this was taken very early on in the car’s development. Using it just to illustrate some of what’s wrong with the car’s front end; odds are if you’ve seen an old Camaro on an autocross course, it looked a lot like this.

Here’s another one from a 1967 magazine article on the original Z28:

That thing has no grip on the crap OE tires, but it still manages to showcase how utterly whacked its front suspension is.

Front grip is tremendously important in autocross. At the track if you’ve got way more power than everyone else, you can maybe get away with a pushy (understeering) car, heck, it’s more stable. But not in autocross. You need to generate big yaw/rotation, and you need to be able to change direction quickly. The front tires do all this work and it’s the front suspension’s job to keep the tires as happy as it can.

Pretty much nobody with one of these old cars is giving them enough front tire. I’ve seen cars with $10k+ in aftermarket grafted-on C6 subframes, uber expensive shocks, and mega-$ forged wheels … wrapped in 245 width tires! With 335s out back! That sort of stagger might work on a 911, with over 60% of its weight on the rear axle, but it’s a recipe for terminal understeer (and a frustrating/boring driving experience) in a 55% front-weight Camaro. If you want one of these things to turn, you need to give it all the front wheel/tire you can, and nothing made today with a DOT stamp is “too much”. My Viper had about the same front weight as most of these Camaros, and it had 335s up front! At that size things were just starting to work right. 🙂 Obviously packaging is a problem but with all the effort put into everything else, I don’t see why more of those guys aren’t running at least 285s up front.

So to the subject of analysis here – the motion ratio – and boy is it TERRIBLE! To many that may not mean anything, so let me attempt to explain. Below is a photo of a stock ’67 Camaro lower control arm. At the far left, the rod illustrates the axis upon which the arm pivots. At a bit past 8.5 inches down the tape measure, are the two bolts that hold the shock. When installed, the spring sits concentrically around the shock. At the far end, just under 16 inches, is the lower ball joint’s pivot point. Though you can’t see it here, there’s a hole for the stock swaybar attachment at about 13.5 inches.

So what’s the motion ratio, and why do I care? Well, the motion ratio, is the ratio between how far the wheel moves, compared to how far the shock absorber (or spring) moves. The further out on the arm the spring/shock attach, the higher (and better) the motion ratio. To calculate the motion ratio, you take the distance from the inner pivot to the spring/shock attachment, and divide it by the distance from inner pivot to lower ball joint pivot. If we round the pictured measurements a bit, we get:

Motion Ratio = 9/16 = .5625

This means, for every inch of wheel movement, we only are going to see .5625″ of spring/shock movement. Okay, so why’s that bad?

It’s bad because we depend on our shocks to damp the motion of both our unsprung (wheel/tire, 1/2 our suspension) and sprung (the rest of the car) weight. The better a job the shock can do, the more consistently loaded our tires will be, the more grip we’ll have, the faster the car will go around the corner, the lower our laptimes. This motion ratio is about 30% lower than the motion ratio of a good modern car.

Below is a pic of a Viper’s front corner – look at how the spring and shock attach waaaaay out on the arm, right next to the lower ball joint:

The Viper enjoys a much much better motion ratio than the Camaro.

Shocks depend on velocity to do their job – if they are not moving, they are not displacing fluid, which means they aren’t doing anything. The more shock travel we can get per unit of wheel travel, the better we can control every microscopic bit of that wheel travel. This also allows us to control things with lower shock forces, which makes it easier to find reasonably priced units.

In an autocross car with a good motion ratio, we’re generally looking for what the shock does at about 3 inches/second on a force vs. velocity graph (explained somewhat here: http://farnorthracing.com/autocross_secrets20.html ). Most of the movements the suspension sees on an autocross course are in this speed range, so that’s where we care about what our shocks are doing. Shock velocities above that speed (bumps) are important too but somewhat less so, they’ll be a subject for a later day.

So getting back to the Camaro – with a motion ration of .5625, we’re only getting about 2/3 the shock travel or velocity, of a “good” suspension car. So whereas they get to build their shocks to work at 3 in/sec, ours have to be doing the same quality of control, with 2 in/sec. The problem is, accurate control and large forces at these low shaft speeds, are very hard to come by – any of the common shocks available over-the-counter just aren’t going to get it done, at least not very well. But wait, it gets worse!

Spring rate by itself is a not very good indicator of how stiff a car is – what’s more useful is the “wheel rate”, or maybe the “natural frequency” of a suspension. Here’s an online calculator if you’re interested to find out yours: http://www.racingaspirations.com/?p=292

Those that have ever ridden in an unladen 1-ton pickup truck, and been bounced all around, have experienced a high wheel rate, and a high natural frequency. The high natural frequency is caused by a very high wheel rate, combined with not much weight on the spring (an empty truck bed). If you’ve ever then loaded up that bed with a few thousand pounds and noticed the truck suddenly rode much more comfortably, it’s not because the wheel rate went down (in some leaf systems, it might actually have gone up) – it’s because the natural frequency has gone way way down due to the weight/load in the bed.

We arrive at wheel rate by taking the motion ratio, and multiplying it by itself – “squaring it”, in math terms, then multiplying it by our regular spring rate. In the Camaro’s case, .5625*.5625=.316. That means that for every 1 pound of spring rate, we are going to have .316 pounds of wheel rate.

Wheel rate and natural frequency are concepts you can use to compare the stiffness of any two cars, regardless of suspension type. You’ll often see sliding scales where 1hz is “comfy street car”, 1.5hz, “sporty car”, 2.0hz “race car”, 3.0+hz “race car with aero downforce” – something like that. Those are really just broad generalizations and by no means limits on what you can do with your car.

If you’re setting up a car to handle well, 2.0hz isn’t a terrible place to start. If you’ve driven other prepared-suspension cars that you really liked, that were of a similar layout (RWD, FWD, AWD), it might be worthwhile examining that car’s frequencies and consider it as a baseline. For instance, my 240sx used a 550lb. front spring when it was in STS (street tire) trim. It had a bit over 700lbs. of total weight per front corner, about 55lb. unsprung. It used a strut front suspension which granted a motion ratio of about .96. Its 550lb. spring netted a ~500lb wheel rate, and with the car’s weight, its natural frequency was around 2.7hz. While this was way higher than anybody is likely to recommend for a daily driver, it wasn’t terrible on the street, but more importantly, it wasn’t so stiff that the street tire wasn’t working well. The car worked great!

If you’re setting up a car to handle well, 2.0hz isn’t a terrible place to start. If you’ve driven other prepared-suspension cars that you really liked, that were of a similar layout (RWD, FWD, AWD), it might be worthwhile examining that car’s frequencies and consider it as a baseline. For instance, my 240sx used a 550lb. front spring when it was in STS (street tire) trim. It had a bit over 700lbs. of total weight per front corner, about 55lb. unsprung. It used a strut front suspension which granted a motion ratio of about .96. Its 550lb. spring netted a ~500lb wheel rate, and with the car’s weight, its natural frequency was around 2.7hz. While this was way higher than anybody is likely to recommend for a daily driver, it wasn’t terrible on the street, but more importantly, it wasn’t so stiff that the street tire wasn’t working well. The car worked great!

A similar calc on the rear of an STS Civic I built, puts the frequency around 3.5hz! Some guys I know are running springs up in the 4-5hz range on the rear of those cars.

So getting back to the Camaro, now knowing the 240’s numbers (500lb. wheel rate, 2.7hz) as a ballpark. With our Camaro’s motion ratio, to get a 500lb. wheel rate, we’d need (500/.316)=1582lb. springs! Even at that rate, our frequency is only going to be a bit over 2.5hz, in some ways softer than the 240sx. To get to the same frequency I’d need springs up around 1820lb./in!

Ugg, now we’ve got not much shock velocity to control our wheel motion, and on top of it, we’re going to have to run crazy stiff springs to get this thing to the stiffness level we want.

There are a lot of things “less than ideal” about the Camaro’s front end geometry – bump steer, camber curves, etc., that I can’t really fix in ST, and that you can’t really fix with the stock subframe. In an earlier post I mentioned my plan for dealing with these was to set the static numbers good and “not let it move much”. You can see now why people hadn’t really tried that approach before – they couldn’t! No normal shock you could buy off the shelf would damp a 4-digit spring given an equal motion ratio; things that stiff were just outside the bounds of people’s thinking. About the stiffest I’ve seen anyone run is 800lb. springs, for a 250lb. wheel rate, about half what I’ve depicted above. It’s no wonder people were so concerned with bump steer and camber curves – at that low a wheel rate, the suspension would experience large (double to triple) the quantity of travel as the more stiffly sprung version, so the negative effects of bad bumpsteer/camber curves would also be doubled or tripled. It also means they had to run their cars a lot higher, which is a Big Bummer for them, we’ll explore later.

So to bring this home-

Bad motion ratio gives shocks poor control of sprung/unsprung motions, leading to inconsistent tire loading

Bad motion ratio creates a lot of suspension travel at “normal” spring rates, exacerbating the problems with the stock suspension’s camber and bumpsteer curves and necessitating higher front CG

How am I going to avoid letting this screw me up? Simple answer – great shocks! The 28-series Konis I have, were originally designed a few years back for high-downforce Indy cars, where there are very large forces needed at very small suspension displacements. Even though an autocrossing ’67 Camaro is a long ways from a recent Indy car, the characteristics needed end up being quite similar. There are many other high-end brands (Penske, Ohlins, Moton, AST, JRZ, Sachs, and more) than can get this done too, Koni just happens to be the one I’m most familiar with. With a little bit of revalving, they are going to allow me to run these really high spring rates, while maintaining good wheel control, something a lower-end shock wouldn’t.

Lots more wrong with front suspension, more to come on that later…

Agricultural 12-bolt and down the rabbit hole

Some of the parts needed for this build are getting harder to find, this is one of them.

The GM 12-bolt is an extremely robust rear-end with an 8.875″ ring gear. It is often compared to the ubiquitous 9″ Ford rearend, the GM piece being a tiny bit less stout, but more efficient (less driveline hp loss).

I’ve been looking for one for a while, and one turned up on Craigslist. The price was good, picked it up Friday.

It is a correct ’67-built Camaro piece. According to the owner, it had been sitting in storage for about 20 years, and then in his yard for the past several months. Based on the dirt removed, by several months, he might have meant 120 months!

Inside the brake drums, an entire ecosystem was flourishing, all sort of spiders and insect carcasses abounded. In this pic you can see the huge black spider that “owned” the passenger side drum-

I don’t think I should count all that dirt as weight reduction, pretty sure it wasn’t there from the factory 🙂

Getting this thing in shape is going to be a bit of work.

My plan was/is to get the car minimally prepped, so I could take it to a welder and have all the big on-car welding projects done. I have taken a welding class, and have access to a good MIG, but don’t trust myself to weld anything critical, like a live axle lateral suspension locator.

The lateral locating device will be attached to the rear axle, so the axle needs to be clean and ready for welding. I also wish to package the device towards the end(s) of the axle. The limit of how far towards the end the device can be located will be defined by the brakes. Hmmmm…down the rabbit hole we go………..

So it looks like maybe I should get the rear brakes put together to ensure I don’t get welded into a packaging dead-end. Now, STX does have a “big brake kit” allowance. Unfortunately, like many of the ST category’s allowances, it is a rather Fisher-Price allowance (“My First BBK”). I can say that, having spent a few years on the STAC – aka the Street Touring Advisory Committee, the “subject matter expert” rules making/advising group for the ST category. I get what they had in mind – the blingy cross-drilled stuff you see in the tuner magazines that are easy bolt-ons for popular cars. Nothing exotic, no messing with the hydraulic system, nothing requiring any engineering on the part of the ST car builder, just bolt-on kit/kid stuff.

Now, there are plenty of “bolt on” kits for the first-gen Camaro. However, none of them are really designed to work with the factory master cylinder, which is rather large (1.125″ bore). Those kits all come with some kind of late-model Camaro or Corvette master cylinder, often with a proportioning valve.

Can’t change the master cylinder, can’t change the booster, can’t add a proportioning valve – at least, not in the classic fashion. Some first-gen Camaros came with a proportioning valve, but that was only the heavier cars with A/C, not the Z28, and even if it did, I couldn’t change it.

The flexible brake lines I can change, the calipers and bracketry I can change, and I can use any rotor equal to or larger than the diameter of the factory rotor or drum. Even the smallest aftermarket stuff is about 12″ (stock drums are 9.5″) so the diameter won’t be an issue. Since the calipers themselves are free, I was thinking I could use one small proportioning valve right at the inlet to each rear caliper. Then I could say it is part of the caliper and thus legal. I expect to receive emails from people saying “hey, that’s not what they had in mind” shortly 🙂

But I’m not totally sure I even want to have a proportioning valve. The Viper had one when I bought it. I ran it that way for a couple events (nothing National, folks). The car from the factory had shorter front tires than rears, and the previous owner raced it with equal sized tires all around. Taking the car back to Stock, I removed the valve as it wasn’t legal, or needed. When the Viper was on the ideal f/r diameter tires, I thought its brakes were the best of any car I’ve ever driven, and a lot of that was the factory blessing the car with a healthy amount of rear bias. When I ran a slightly (.6″) taller front tire, it would try to kill the driver with too much rear bias. So, suffice it to say, there isn’t a ton of room for error in sizing the brake system, but the proportioning valve does give you a bit more leeway.

I won’t go too far into designing a brake system here, but there are several key variables to consider. In my case, some are fixed, some I know or can estimate, and some are free to change.

Fixed:

Master cylinder bore

Brake pedal ratio

Brake booster ratio

Proportioning

Known/estimated:

Static front weight

Static rear weight

Wheelbase

CG height

Maximum deceleration (use this to calc load on front and rear tires at max decel)

Front and rear tire diameter

Free:

Rotor diameter

Caliper piston area

…from all this there’s a bit of thinking to do. You can design a perfect system on paper, but if the parts don’t exist out there in the world, it doesn’t do much good. Not going to have custom calipers made for this. Have to see what is available from Wilwood, Baer, Brembo, Stoptech, etc., and piece together a working system from their available components. Also have to consider – is the car going to get track time? Autocross puts much less demand on brakes than does the track. Most of my track experience is in the S2000, which had somewhat undersized and undercooled brakes, a constant problem.

If the car isn’t going to see much hot lapping, then 12″ rotors will probably be fine. If it is going to be tracked hard, I’d probably want 14″ rotors, as I plan to run only 18″ wheels, and they’d provide the ultimate in thermal capacity. The bigger rotors are heavier though, a disadvantage at autocross. 13″ rotors might be a good compromise. The larger diameter rotors also provide more brake torque with all else equal.

Speaking of weight, the stock rear drum brakes weighed 43 pounds between the two sides. In my STX Z28 spreadsheet, was anticipating losing 7 pounds in rear brakes, would like to stick to that if possible. Also have to retain some kind of parking brake, which adds weight.

Browsing Wilwood’s brake kit chooser site:

http://www.wilwood.com/BrakeKits/BrakeKitApp.aspx

They ask about the axle offset. Hmm. Didn’t have the axle apart enough last night to get this measurement, and even if I did, am I sure it would be right? I’ll be changing the limited slip, and didn’t know if the axles in there were the stock size and length. So one more trip down the rabbit hole, might as well get my limited slip now, with OEM replacement axles (no donuts here Civic guys! ;)), so I can put all that stuff together and measure my axle offset properly. Will need the measurement to be final and exact regardless of whether or not Wilwood stuff is chosen. They list three sizes, 2.75, 2.81, 2.91. Again, not much room for error here!

Will go into a discussion about the limited slip choice later. One somewhat unfortunate thing, is the GM 12-bolt isn’t the hottest diff out there, so it doesn’t have all the fancy choices some other cars get. I’ve had excellent experiences with ATS/Carbonetic in the IS300 and 240SX, and the OS Giken has gained huge popularity in autocross circles as of late. Still, there are some tried-and-true options for this car I think I can make work fine.

So I got things a bit further along today. Didn’t try measuring the axle offset, figured the bug guts might throw it off by .06″ anyway.. 🙂

Whole thing covered in funk and some kind of white paint, got most of it off. As bad as it looked on the outside, the insides look great. Everything very straight and true, turning very smoothly. It had a 3.07 open diff in it, so it’s not likely to have seen much heavy use. The gears all looked better than any of the Viper diffs I’d worked on!

Oh, and speaking of gears, one cool thing about old cars, is you had LOTS of choices-

http://camaros.org/drivetrain.shtml#AxleCodes

…and the Z28 could be ordered from the factory (unlike the dealer-installed cowl-induction or header options) with just about any of them. 3.73 standard. These days, you have to order a whole big option package or something to get a different rear ratio, you never get to choose it individually.

Non-terminal steelitis

Some cars are really good from the factory and need little help to be made made super good. Other cars are not so blessed, and need lots of help.

Something I’ve seen a lot of in modern performance cars, particularly turbocharged ones, is a proliferation of “magic little boxes”. One of them is a manual boost controller. Another is a turbo timer. Then there’s the other one to play with the A/F tuning and cam timing. Before you know it, there’s half a dozen little black-box warts all over the interior with their knobs and wires everywhere. Yuck! I hate that sort of clutter, magicboxitis you might call it.

“-itis” is often used as a suffix to describe an inflammation of the -whatever, maybe it’s the tonsils or the colon.

The thing I’ve seen happen with these old muscle cars is a sort of steelitis. The answer to almost every problem is to bolt or weld in some beefy looking steel braces. Subframe connectors, watts links mounts, additional crossmembers for conversion to 3 or 4-link, roll cages, and extra tubes and braces in the engine compartment. Certainly, when done right using good straight paths, these things can be helpful and effective, but so often the cars end up like tanks – strong but heavy. Leaving one to wonder if the car is really any faster than it would have been with a flexible chassis, minus the 200lbs. of steelitis.

A big goal for this car is to keep the weight as low as possible – both in quantity and location :). I’m going to be competing with better-balanced cars on the same size wheel/tire (well, many of the BMWs run 255s, but it’s close), so I have to do everything possible to keep my weight in the same range as them. The RX8s are 26xx with about 50/50 weight distribution, the BMWs in the mid to low 2800’s also around 50/50 and the Subaru WRX in the mid 2800’s, with AWD, but nose-heavy and on 245’s.

I had a huge 33% (650lb.) weight disadvantage to the Civics when I ran the 240sx in STS, but I had some big advantages there too in bigger/better tires and RWD. I think I can get the Camaro’s race weight a lot closer to the BMW and WRX weight than people would expect. Doing so will be critical as I won’t have any sort of tire or drive type advantage.

To make it light, I will have to aggressively treat any steelitis flareups that occur, which is difficult because there are lots of pretty steel parts out there begging to be put on the car. One slipped past my steelitis immune system today, the subframe connectors-

Actually I had made up my mind weeks ago to use these parts, and having them in hand was a prerequisite to the first big set of work I’m having done by someone else, which should be starting in a couple more weeks.

ST allows for bolt-in subframe connectors, which these are. From a design perspective, I like them for a few reasons – one is they tuck up nicely next to the rockers, which should make it easier to get a good middle point of attachment between the SFC and rocker panel. It also reduces the ground clearance hit from the parts; the car is going to be very low, and with the limo like 108″+ wheelbase, the car is going to want to high-center getting on trailers and stuff. They’ll also make it a piece of cake to jack up the car from the side.

But man, the pair weigh 24 pounds!! See, that undoes my 11lbs. of weight savings in rear springs, and another 13 pounds of savings from the HVAC system. On the steelitis mitigating side, they are sprung weight, very very low in the car, fully between the axles so the “cost” of that weight is about as low as it gets, but still, ouch.

A quick aside about chassis stiffness. People tend to go overly gaga about chassis stiffness and torsional rigidity. The new Ferrari has 1x,xxx ft-lbs/degree of stiffness, the McLaren has this, that, whatever. While important, I think it tends to be mostly overrated as a goal for people working with autocross cars, particularly those that won’t be running on big wide slicks. The reason we need chassis stiffness is so that our suspension tuning actually does something. If we want one end of the car to offer relatively more roll resistance than the other, our tuning efforts will be stymied if our stiffening of that end gets absorbed by additional twist in the chassis. If the car is responsive, has the balance you want, and is generally predictable to drive, then you aren’t going to find a ton of time in additional chassis stiffness. In most cases, you will probably make the car slower, as the additional stiffness comes at a huge weight penalty when the car builder succumbs to terminal steelitis in the form of multiple strut tower bars, fender braces, 24-point roll cages, etc.

One other thing to note in the picture above, the little white cylinders. Those are delrin bushings for the front subframe. Delrin is a hard and durable plastic that doesn’t really compress, unlike the rubber bushings used in those spots by the factory. In conjunction with the subframe connectors, those little guys will do a lot to “lock” the front subframe to the body of the car, and add some stiffness to the overall structure. If our rules were more open I’d probably use aluminum in those spots because it’s a bit tougher, but we aren’t allowed to use metal bushings. The Delrin should be fine really. These bushings aren’t the whole subframe/body interlock story, there’ll be more coming later, stuff I’m still working on.

Further suspension dissection

Got a bit further into the suspension today.

Thought I’d start the day by pulling the seat covers off the rear seat frame, to help get rid of some of the smelly funk in the garage. I had planned to maybe replace the whole thing, but each frame for the bottom and back is bucks ($600+) so figured I’d strip it down the the frame, powdercoat, then re-cover.

There were TWO covers on the bottom! Instead of re-covering the original, someone put a new black cover over the original blue vinyl. All this mess was held in by a million of the little metal bent staple things. Probably a pound weight savings right there! Will be nice to have that stinky stuff gone but doing so burned a ton of time.

So on to the rear suspension. Got the rear axle free of the springs and brake lines, and jacked it up to around where I figured its “working” ride height would be. Wanted to see how much room there’d be to package the gear I have in mind for back there-

Looks like 5″ from this pic but it’s really more like 4-4.5″. Will probably be enough for what I want to do. I imagine some people are expecting me to introduce some kind of new-fangled cutting edge live axle lateral locating device, but unfortunately for them, I have no such plans. Effectiveness, light weight, and simplicity are the goals. Surprisingly, none of the big aftermarket vendors for these cars make a simple panhard rod kit. There are a few watts link kits out there, but they all look very heavy.

Below is a simple and effective lateral locating device found on a very successful car.

From the factory, the car depends on the leaf springs to function as the springing medium, but to also control the axle’s lateral, longitudinal, and torque movements. In a way this is really clever, as you don’t need all sort of control arms and bushings, it is all really simple. Unfortunately as with anything you ask to do too many things, the leafs end up compromised and not doing any one of those tasks very well.

Below are the leaf springs I plan on running, at least initially. I have to stick with leaf springs per my rules, can’t go to coils, and things like springs embedded within the shocks are also not allowed. I could try to do some sort of crazy progressive bump stop tuning to use those as the spring, but I don’t like bump stops and don’t plan on running any.

These are Hypercoil composite leaf springs, one of them side-by-side with a stock mono-leaf rear spring. The Hypercoil spring here is 250lb/in., and has about 3″ less “arch” than the stock spring. I suspect even with that much less arch, the rear of the car is going to be too high for my purposes. The spring I pulled off the car had a rate probably around 80lb/in. The ’67 Z28 had a stiffer stock rate, probably around 125lb/in. Double that rate sounds high but I don’t suspect it will be, as tire and shock technology has come a long way.

This will give the rear a ride frequency just over 2hz, which should be in the ballpark. There is no real “motion ratio” for a live axle in ride, a 1″ suspension movement equates to 1″ of spring compression.

Ride height adjusments aren’t very easily done with longitudinal leaf springs, so that’s something I’ll have to work out when the time comes.

Oh, these composite rear leafs as a pair are over 11 pounds lighter than my super-soft stock rear steel mono leafs. Not a huge reduction, but for a car using big multi-leafs to achieve a high rate, probably lots more weight to be lost.

The front fares a bit better. It uses a traditional upper and lower a-arm suspension, albeit with really awful geometry. It’s funny to see, at full droop, the car actually has several degrees of negative caster.

The stock spring is 16″ long! 16″ also happens to be the effective length of the lower control arm – the distance from their inner pivot point, to the center of the lower ball joint.

The shock mount and spring seat is centered at a distance of 9″ from the inner pivot point. This gives a not-too-great motion ratio of .316. What this means, is we don’t get a lot of travel at the spring/shock for a unit of travel at the wheel/tire. This necessitates higher spring rates, and shocks that can properly handle those higher spring rates. Fortunately I have a really great set of shocks left over from the Viper, so I should be able to get the valving I need. I haven’t seen the motion ratio for a first-gen Camaro published before and didn’t know how it would be until I put the arm on the workbench today. Seeing it now I’m not surprised people have trouble getting them to work well with stiff springs. Unless you go to a custom arm that really improves the motion ratio, you’re going to need a shock capable of massive low-speed damping to keep one of these front suspensions under control.

My STS 240sx used 550lb. front springs with a strut suspension that provided near a 1:1 motion ratio, its wheel rate was around 500. That was pretty high for a car that only had about 700 pounds on each front corner. Like the Camaro, it had really bad suspension geometry, especially when lowered, so I used a fairly high spring rate to keep it from moving too much; it also had a sharp fender seam that would cut into the tire on a bad bump.

To get an equivalent wheel rate is going to require a spring rate well up into the 4-digit range, over 1500lb/in. by my calculations. I probably won’t go quite that stiff, at least not at first, as I plan to use a stiffer front sway bar on the Camaro than I used on the 240sx. The stock spring rate on my Camaro was around 330lb./in, the Z28 of this year only had about 380lb.in.

I believe it was Colin Chapman who was credited as having once said “Any suspension will work…if you don’t let it”

My interpretation of this sentiment, is that if you can set your static figures (camber, caster, toe) in a good and happy place, then just not let the suspension move very much, you are probably going to be okay. Things like camber curves and bump steer curves are important, and if you’re in a class where the rules allow you to properly re-engineer those things, doing so is worthwhile. But if you aren’t allowed to re-engineer those things, and are dealt (or choose) a car with crummy bump steer and camber curves, then give the car plenty of static negative camber (I ran -4.5 degrees on the 240sx) and make it stiff enough so the outside front tire is still in a “happy place” at terminal roll. Sure, your inside front tire may be riding on its inner edge, but especially in these big heavy production cars, the outside tire does pretty much all the work in the corner anyway.

So the above summarizes my philosophy and approach to how I plan to make the front suspension on this car work. It’s going to have a lot of static negative camber, people will probably think it looks funny. Donohue never figured out a way to get the front of his car to work without a ton of static negative either, so who am I to try?

I’m also a big fan of adjustability, so the finished front suspension will fully adjustable for ride height, camber, caster, and toe using a combination of both the factory methods and the allowances we have in ST for camber kits and replacement control arms. I think it is important as a builder to give yourself a wide range of adjustment, and to never be at the extreme of any adjustment range you have. You should always have one more hole, or shim, or click of the knob to go in any direction, at least under normal circumstances (i.e., a normal dry surface).