Motor and goodies and getting it going again

Soooo…. what’s happened with the Camaro over the last 3 years…

What started as a fix-up-a-few-things quickly snowballed into a big mess. I’d really been burnt by all the valvetrain failures in STX trim and wanted to shore that up. The car was never going to be competitive again in Street Touring, and it didn’t/doesn’t really have a fit in Street Prepared or Street Modified either. There’s a lot of unlimited-style builds out there where the cars are legal for CAM class but not much else – I didn’t want to go that far, nor do I want to cut it up in the mold of a traditional CP car.

Much of the time spent over the years was just deciding on the vision for how the car will be in its next iteration. Where I arrived is at something like a light CP build, that can also run in CAM with some ballast. I’d like to get it down near 2700 pounds using a < 5.1 liter motor, so it’s CP legal weight-wise, but it’ll keep the lights and wipers and things that are needed for CAM. For now I just want to make it drivable again but it’ll get a quieter exhaust, bigger wheels/tires (with room to turn), and better suspension.

Ordered a set of AFR aluminum heads, sized a bit on the small side (180cc) to maximize midrange torque from the 302 short block. Mike Jones did a nice bumpity solid roller cam for it, and I had ProSystems build a mechanical secondary carb to match.

Was originally going to try to hot rod the thing with the block kept in the car, but with the trans out it all became a bit of a pain, so I pulled the short block out too, so I could assemble the new motor on the stand.

With the short block out, might as well check the bearings and things, since some metal had been through the motor once or twice with the valvetrain failures. Plus oil pressure had gone to zero – or very close to it – several times under hard braking.

Unfortunately in this check, found some pretty serious scoring on the rod and main bearings. The dilemma now, have this (old, 60’s GM, 2-bolt-main) short block repaired, or just get a new one? I opted for the latter, a basic Dart SHP cast iron piece, a 4″ bore 3″ stroke, from Chris at CNC Motorsports. Only special ask was to use 6″ rods over the default 5.7″, though it probably won’t make much difference.

So what had started as a simple bolt-on hot rodding project was now a completely new longblock needing assembly. A bunch of things you’d think would be simple and sorted in SBC, weren’t. Finding a set of rocker arms to clear the big retainers of the extra-zoot valvesprings I’d had AFR spec, was one tricky part. Had to use lash caps to get it to work with the right valvetrain geometry.

The other tricky part was the oiling system. Used a similar but new Milodon roadrace oil pan (dipstick on other side with this block), but had a hard time finding an oil pickup that’d clear the internal baffle system. Eventually found the parts needed to go along with one of the Melling shark-pattern oil pumps.

With it all put together it went into the car over 4th of July weekend 2017.

The OEM ’67 belt system was a catastrophe so a March setup replaced it. The old-school alternator is replaced by a high-output one-wire, belt driven water pump now electric. Valve covers provide extra internal clearance for the rocker arm setup. They should provide room for a shaft mount system if things ever go that way.

My invaluable engine install helper:

There was still lots to do. The fuel was years old at this point, the wiring was a mess I wasn’t happy with, trans needed install. Another sign of not having gotten over 2013’s valvetrain drama was my insistence there be room in the engine bay to pull the (oversized) valve covers quickly and easily without too much stuff in the way.

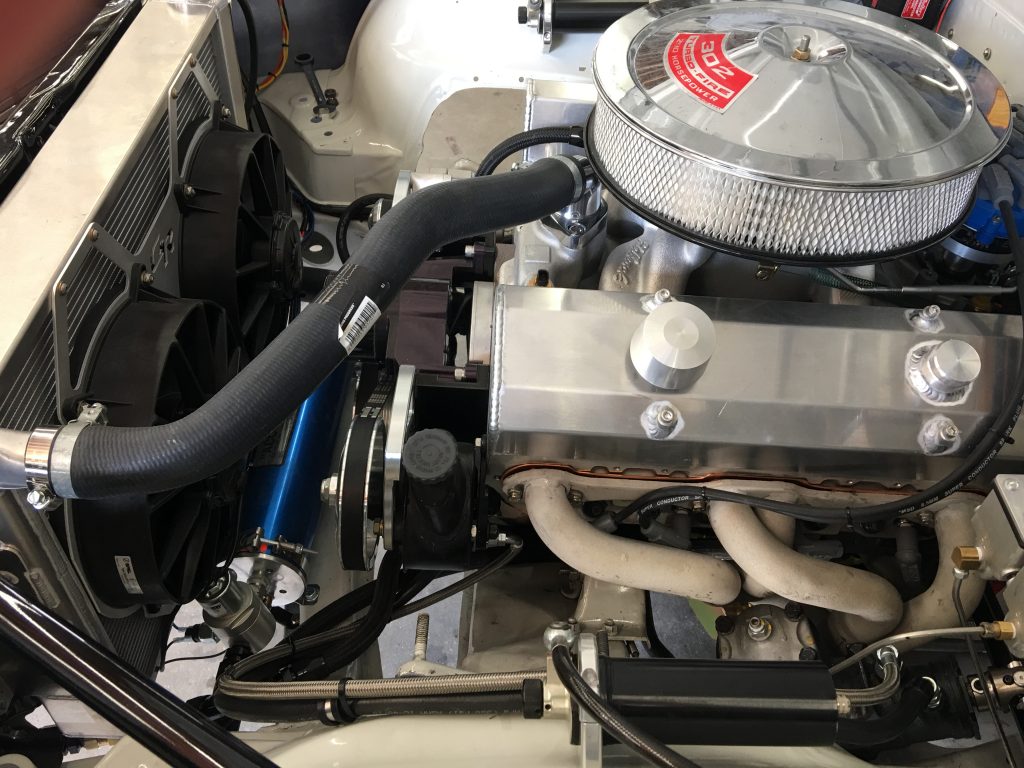

Here’s how it sits today – many many hours of labor later-

Coil is relocated up and out of the way. The big brake booster and heavy cast iron master cylinder have been replaced by a small and lightweight (20+ pounds saved!) manual balance-bar system.

The aluminum radiator and dual electric fan setup is from C&R. Can’t see it but in front of the radiator, there’s a modestly sized C&R oil cooler with remote oil filter mount. The filter was a nightmare to get to with those headers, should be tons easier now. I’d run a cooler on the 370z and saw what a tremendous difference it made in oil temps. This cooling system is overkill for a little 450-ish hp (hoping, not sure exactly) 302 but

The Accusump with EPC valve is housed down there in front, nice short run to the motor from the unit. Placement of these things is always an argument between the chassis guy and the motor guy – motor guy wants it close to the motor, chassis guy wants it back to favor CG. Motor guy won here.

From the other side, showing the new mechanical fuel pump-

With work and life and everything I haven’t had the spare time to give the car what it needs. It’s at Best of Show Coachworks in nearby Escondido, where Dean (mechanic) and Matt (owner) are doing a really fantastic job with it. I’m much happier with their work and the progress being made than I thought I’d be, as a consummate DIY-er.

Motor should be running again soon..wiring is still being fixed up, I’d done some naughty things to get it put together on time, Dean is repairing all my badness…

Exhaust buttoned back up:

Last bit is on the suspension. The OE style spring-over-shock thing was a mess I really didn’t like, so the car is getting the ATS upper coilover mounts. This will simplify and clean up how the what is now a front coilover, mounts to the chassis.

Still brainstorming with Matt on how to improve the motion ratio, by altering some aftermarket lower control arms to locate the coilover’s lower mount much further outboard, closer to the lower ball joint. May eventually do some custom fabbed arms and spindles and things but for now, looking for improvements to off the shelf pieces.

More to come in the coming weeks!

Leave a Reply

You must be logged in to post a comment.