Turning over some new leafs

Most people think of a leaf spring suspension as a drawback, and in many ways it is, but I also find it one of the more interesting challenges in developing the car.

Unlike a traditional coil sping – which is only responsible for holding up the car – leaf springs are multitaskers, as they control axle location and wind-up, in addition to holding up the car.

The original composite leaf springs for the Camaro had it way too high – might be ok for a stock-height car, at a much-heavier-than-stock rear weight (which my car is not) – so, about 3″ too high, even with a 1″ spacer block.

The next set, what’s on the car now, was better – the lowest ride height Camaro design Flex-a-Form makes. They require only about a 1.5″ spring spacer to get the height correct.

Unfortunately while spacer blocks are an easy way to get ride height where you want it, the more you use, the more they detract from the leaf spring’s ability to control the axle. I already saw in San Diego (and at El Toro for the 1 run where the car was launched with full power) that these leaf springs could not adequately control the axle as installed.

One solution is to install a torque arm system. These are big beefy (Steelitis anyone?) members that rigidly connect to the axle housing, and run forward, up to a crossmember by the transmission, which manage axle wind-up under acceleration and braking. Big, heavy, and difficult to implement legally under ST allowances – things to be avoided if possible.

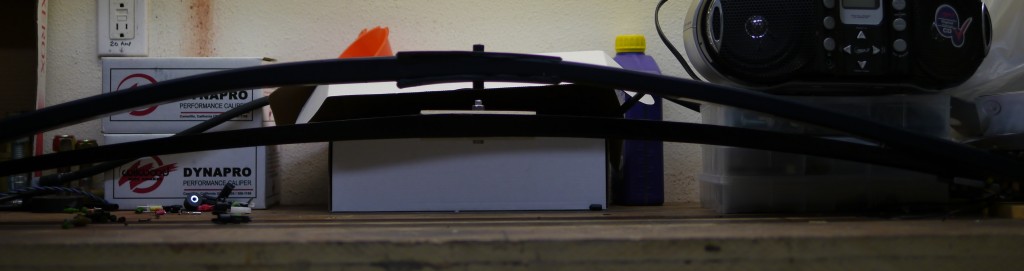

So instead of a torque arm, trying instead to manage the situation better, with a new set of leaf springs. There’s a couple aspects of spring design that can help.

One is to make them flatter, to enable the use of less spacer block. Since Flex-a-Form had already made their lowest possible ones on their regular Camaro die, they had to try something else, which was the use of a different die, used for transverse Corvette springs. This produced a flatter spring, though in looking at it next to one of the original Hypercoils, am not sure it is flat enough. Will have to get these on the car, to see how much spacer block is needed – hopefully little to none.

The other thing, was I had them make the forward section of the leaf up through the spring mount area, extra thick, while thinning it out in the rear section. The middle and forward section of the spring are the portions most responsible for longitudinal location and managing axle wind-up, so some extra beefiness there should bolster those strengths, while the thinner rear section keeps the overall spring rate in the right range (approx. 250lbs/in. for now).

Leave a Reply

You must be logged in to post a comment.