Springs and shocks

Springs and shocks arrived recently from ProParts USA. When putting together a suspension the actual shocks and springs are just a part of what’s needed. You want to take a look at how they connect at either end, and take advantage of any improvements possible.

ProParts built a nice set of custom aluminum top hats for the front and rears. Gone are multiple rubber elements, replaced by spherical bearings. The front shock lower mount is also a spherical.

One disadvantage of the Koni 30 series is how Bump adjusts. You have to push this button with the shock fully extended, and “click” it through its range.

In the rear it’s not too bad actually, as the spring is separate. The front will be trickier with the spring in place.

So I put things together with some spring lengths based off what I’d seen on the always-right Internet. 6″ front and rear. Of course there is huge variation in this stuff, and 6″ ended up being quite a bit short at both ends.

Here’s how the car looked with the adjusters at max height front,and about the midpoint rear, with 6″ springs:

Heh, yeah, a bit too low. At this height the front upper control arm is resting on the chassis, and the exhaust is about 1″ undergound (if the car weren’t up on dollies).

The above is one I took while the car was like that. Good news is the bump stop was still about 1/4″ away from making contact. Yay! 🙂

Based on the path the exhaust takes, I think there’s ~1″ of extra ground clearance to gain by tucking the tubing up closer to those bracing pieces.

The rear spring motion ratio is fairly “soft” on the Z. As best I can measure, the spring is centered a little bit over 10″ out on ~17.5″ long arm.

Fortunately the shock mounts all the way out at the knuckle, providing great chassis and wheel control.

My approach in springing the Z initially is to go a little stiffer in the front, and a little softer in the rear, compared to the fast 350Z’s that are out there – specifically Brian Peters. My thinking is the 370 should be making a bit more power than the 350’s. I want to give the car the best chance it can have of putting it down, especially at a ProSolo. Most of the other fast Z drivers have abandoned the rear swaybar, but I’ll be keeping one (the Hotchkis piece with lots of adjustments) on there for now.

A week or so after I realized the 6″ers were too short, Jeff had Hyperco deliver a fresh box of longer coils to get the ride height out of the weeds.

STR Interior

Not a lot to do here, but it’s done. Upgraded to “how it shoulda left the factory” spec.

Driver’s seat is a Recaro Pole Position. The stock unit isn’t terrible but lacks lateral support. There are lots of good “race seats” out there offering even more lateral support than the Pole Position, but getting in and out of them sucks! This one is shaped about like the Cobra Imola, a good compromise.

Stock shift knob swapped out for a Tomei Duracon. And a little bit of GT-R with the red start button. Seriously, who uses a white start button? 😉

370z Koni 3011 shock dynos

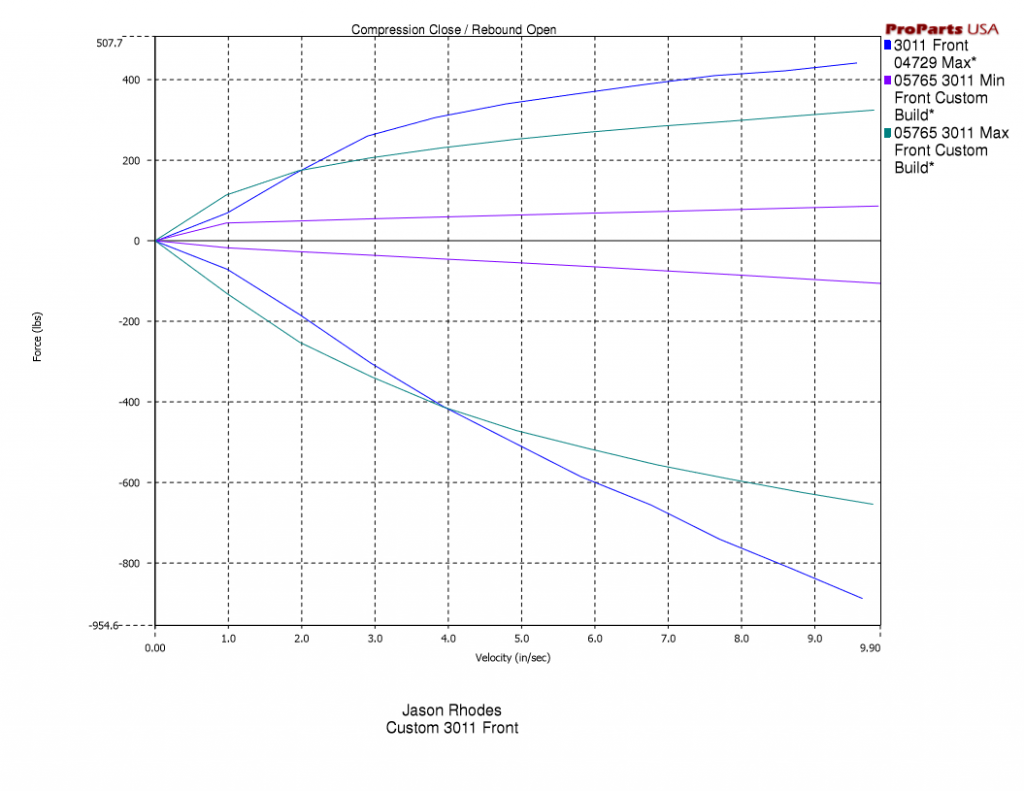

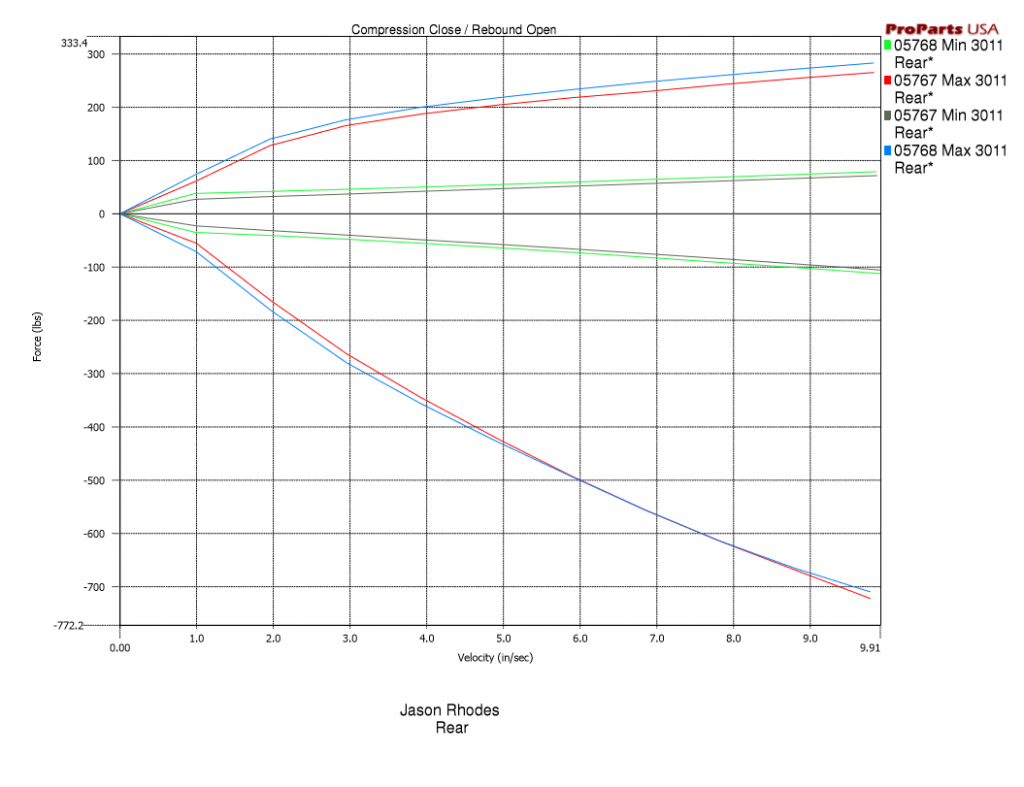

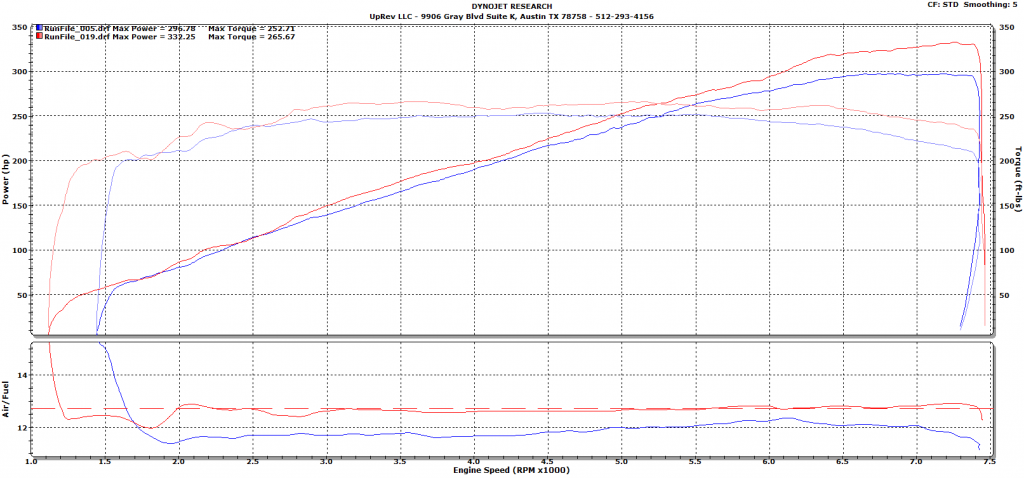

Here’s the dynos from the Koni 3011 shocks I’m having built for the car.

This is my first set of Koni 30 series. I’ve had a couple sets of Koni “yellows”, and a few sets of their high-end 28-series, these are somewhere in the middle. About 2x the cost of a set of custom revalved yellows, but about half the cost of the 28 series.

Their big downside compared to the 28’s, is they aren’t able to produce the nice sharp digressive “knee” at low speed. Also, adjusting bump damping means unbolting one end of the shock, compressing, and rotating it – hardly something you can do when pressed for time.

Still, ProParts was able to produce some quality curves providing a really wide adjustment range centered around where I “think” I want things, in the 2-3in/sec velocity area we tend to operate in most. The wide adjustment range of the 30 series is one of their strong suits.

It’s kinda funny as I remember the 30 series were really popular when I started autocrossing in the early 2000’s; they were all the rage on Honda-Tech. You don’t hear much about them these days but given their racing pedigree, the assortment of qualified builders/tuners, and their competitive price point, they are still a strong choice for those looking for a good street/track compromise shock.

Fronts. The blue line is one of the standard valvings, the teal and purple is what I had ProParts do.

Rear. I am paranoid this car won’t want to put power down at all with the little 255’s out back so I was adamant about having very soft “floors” to the adjustment range of rebound and especially bump.

On the subject of shocks I have some thoughts I’ll work on putting together in a “Page” on this site at some point. I’m not really an expert in the field but there are some extremely common misconceptions surrounding the interaction of shocks with load transfer and visible suspension displacement that I may be able to dispel for my fellow amateur racers.

One more pic

Rear end put back in, minus the suspension. The gray powdercoat on the adjustable Hotchkis rear bar pretty much matches the darker gray used on most of these components.

It’s looking like the last few things needed for the initial STR build will be in next week, hope to have the car drivable again by next weekend.

Further STR progress

This update will be pic heavy, short on words. Here’s some stuff in no particular order.

With the camber arms installed, left front at full bump (control arm in contact with frame) – no rubbing-

This is about 1.5″ from the above, somewhere around where ride height will be. These tires are narrower and about 1.5″ smaller in diameter than stock so there’s lots of room.

Here’s a view at approximately ground level in respect to the car with the corner at full bump. Very low!

Parts returned from the powdercoater. In contrast with the wild colors on the 240sx, went with some understated shades of gray here. Better than the cheap-ish black paint they all had from the factory.

Here’s the engine compartment coming back together, the steel gray powdercoated CAI and strut braces in view.

A shot of the 34-row oil cooler, which mounts to the driver side in front of the radiator.

This picture shows the modification made to the Kinetix control arm to get it to produce some extra negative camber. Need to remove about the thickness of the jam nut (10-11mm) to give enough adjustability to get camber where we want it (around -4, +/- 1 degree).

This last pic shows the Mocal sandwich adapter for the oil cooler. The later 370z’s have the oil/coolant cooler also shown here, and which takes up a bunch of room to make this part of the install really tight in every dimension.

Goal is to make a local practice event in about 4 weeks, and the real season starts up about 4 weeks after that. Still need to install springs/shocks and get things tuned, plus a few other odds and ends…

STR partial progress

The Z is still several weeks away from being road-worthy but some progress has been made.

Started work at the rear of the car – got the diff carrier out and on the workbench. Here it is with the factory viscous freshly popped out, alongside the new Quaife.

I must be getting weak, that thing felt a lot heavier than I remember the R200 in the 240 being. 🙁 The Viper’s rear (which I had in and out many times) was aluminum, definitely not as heavy as this thing despite having to handle 2x the torque.

Oh well, maybe a sign it’s time to get back to the gym!

From there, work continued with removal of half the rear suspension:

And then the rest of it from the other side:

With the suspension all out, removal of the rear subframe is pretty straightforward. Just have to undo a few plastic connectors for the rear ABS sensors and it comes out with 4 bolts.

Although it is steel, there’s not much to it, bet it doesn’t weigh more than 30-40 pounds.

Here’s the subframe and a few other bits on their way out for “processing”:

The five subframe bushings are a painful mess to remove, so I had someone do that part. From there, all these parts – the rear subframe, 5 rear brace pieces, the front strut brace, a swaybar, and a few pieces of the Takeda intake not pictured, went to the powdercoater. They’re a bit backed up so with the holidays, may not have them back for a few weeks.

Lots to do in the meantime!

Put the diff back together with the Quaife.

Of note, its front bushings have been replaced with the new Whiteline poly pieces. There’s only one more bushing it gets, which will go in to the freshened up subframe.

Moved my attention forward. Not surprisingly, the car spilled some more liquified Smurf entrails (coolant) onto its undertray at some time in Nebraska. Makes me feel even better about getting the oil cooler, these cars really can’t take the heat. And I am as mechanically sympathetic/careful as any racer out there.

Things start to look more like an engine in there as the layers of plastic trim pieces are removed. In this pic the front strut (yes I know the car doesn’t have struts but this is what all the kids call them) brace is off, along with some engine trim parts. At the back the little XS Power battery is in position

The intakes are out, as they are being replaced, but also because their removal makes it easier to get to a few key bolts on the next mod, the Berk high flow cats.

Here is a stock cat pictured alongside a high flow unit.

The performance unit offers a significant weight savings, and in the case of this motor, will add significantly to the power level.

Replacing the cats or headers on these cars is famously difficult and I’m beginning to see why. The passenger side one wasn’t that bad, but one bolt didn’t survive the egress.

The other two took a lot of effort to break loose but then came out fine. This one took huge effort, and then snapped right off! The thing is, this car only has 600 miles, and already this portion of the exhaust is completely unserviceable. So, all the folks out there with higher-mileage Z’s that’ve had trouble with this bolt – don’t feel bad, it’s still a problem on an essentially new car. I know exhausts are hot stressful places but this seems like a case of 1960’s British automotive metallurgy 😉

Included the pic above just to show the clean cross-section of the broken bolt. Kinda dreading attacking the driver side cat next. The passenger side has two of the three bolts accessible from above (with suitably long – ~3′ – extensions) but the driver’s side looks much harder from above and below. Hopefully an extra day to soak with some Liquid Wrench will help…

Once that’s done, will move on to an oil change and oil cooler install, the latter requiring pulling the front fascia off the car. Sounds gnarly but with the car this far along it’s supposedly not too bad. Having it apart will also aid in the CAI install.

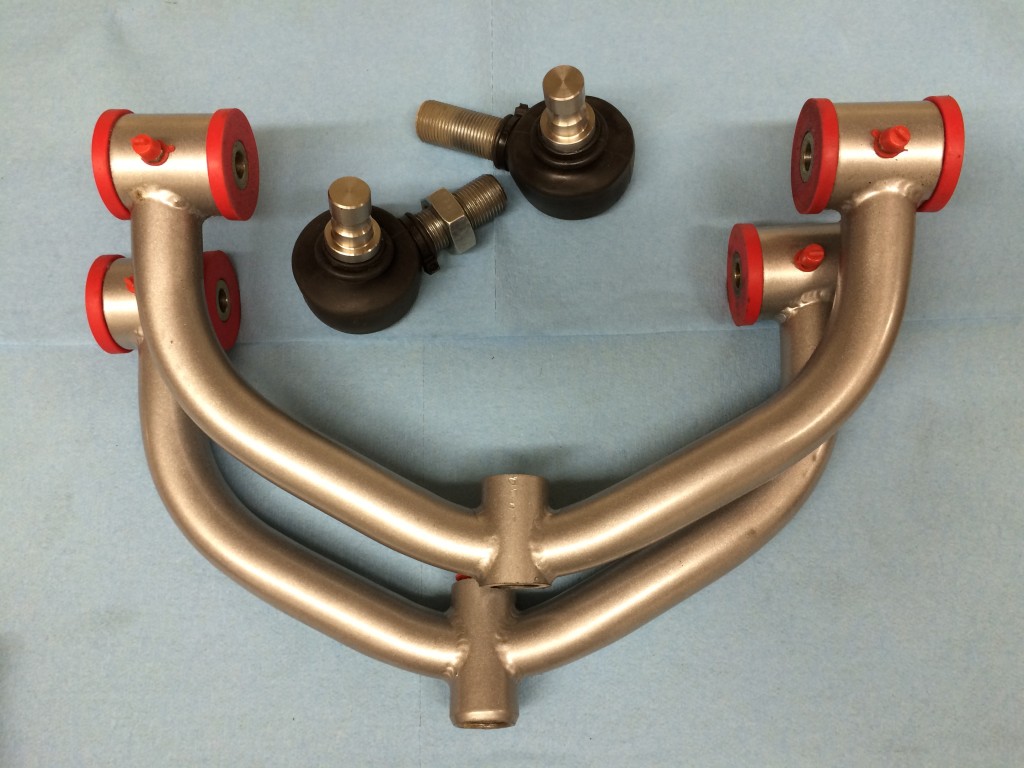

Need to pull the stock front coilovers off, modify the new Kinetix front upper control arms to allow for additional negative camber, and get them installed. New shocks and springs are still a couple weeks out.

Still lots to do but cats aside, it sure is nice working on a clean new car!

Ingredients for the STR recipe

Took advantage of some Black Friday sales to grow the STR parts pile for the 370Z. This is most of what will put the car into its initial state of STR tune.

First thing is what isn’t there – springs and shocks. They’re due in a week or two from ProParts USA – will go into detail on them when they’re here. Will also talk about swaybars then, have a few from the purchases made for Street/Stock-class prep, including an adjustable rear bar I haven’t used yet.

So, going something like left to right-

Black bag is a set of Whiteline poly bushings for the differential. One of the 370z’s most common failures is its jelly-donut of a primary diff bushing. Under hard launches, the bushing quickly croaks and oozes is sticky filling all over the diff and the rear underside of the car:

The diff is held in with three bushings, and this replaces them all with solid poly, no more failures to worry about. This may impact NVH a little on the street, but since the diff is attached to a subframe with bushings, and the subframe is attached to the chassis with bushings, there are still two layers of isolation.

The white box behind the black bag are a set of Prothane poly bushings for the rear subframe. The stock unit is held in with some soft-ish rubber pieces – which help keep NVH to a minimum, but also allow the rear of the car to flop around a little in relation to the rest of the chassis. This leads to inconsistent behavior and response, not what you want in a “race car”. In my experience locking in the subframe doesn’t impact streetability much, but does a lot to make the car feel like it’s “one piece”. Biggest downside of these parts is how they require dropping the whole subframe, which is a bit of work.

That’s the subframe from my STS 240sx from eons ago, had it powdercoated while it was out. It’s remarkable how similar the subframe in the 370 appears. Thinking about giving the 370 a similar treatment, haven’t decided yet.

On top of the Prothane box are a couple cans of Plasti-Dip. Plasti-dip is a somewhat new product (new to me anyway) – it’s basically a rubbery plastic material in a spray can. By applying multiple coats, you form a soft plastic layer over the target part – which can later be peeled off without any change to the underlying part. It has become popular for painting wheels, and some people have even painted their whole cars with it. It’s best when you’re after a matte finish, as it’s hard to get the surface smooth enough for a good shine.

To the right of the cans, you can see a wheel that’s been Plasti-Dip’d. From the previous post, you can see those wheels originally had aluminum centers with black lips:

I used the Plasti-Dip to reverse that setup – the centers are now dark (their “anthracite” color) and the lips are aluminum look. To get that look, you plasti-dip the whole wheel with 5-6 coats of the anthracite, then mask off the center and spray the lips with their aluminum-colored “Metalizer”. Partly because I’m not very good with anything resembling art, they don’t look that great up close. Fine from 5-10 feet though.

Just a recap on the wheels – they are Jongbloed racing 214 model. Very light-weight 3 piece 18×9’s, right at 18 pounds each. They were the first set of wheels I bought for the Camaro. It’s handy how the class-limit width for both STX and STR is 9″, it helps allow for wheel re-use.

The wheels are wrapped in some new tires, the Hankook RS3 “v2″ (200TW version) in 255/35-18. The STR class only allows up to a 255 width tire, while STX allows for a 265. The 255 is of course small, but it technically fits a little bit better on a 9″ wheel (would be better on a 10”) so it should be about the same, if I ever want to run Z take-offs, on the Camaro.

Stock 370Z wheels are great for a factory wheel – made by Ray’s, 19×9 front, 19×10 rear:

Still, being an OEM-spec wheel, and in a big size, there’s weight to lose. These front wheel/tire units will be each be 7 pounds lighter than what I ran in street (2lb. tire, 5lb. wheel) and rears 12lb. lighter each (6lb. tire, 6lb. wheel) for a total wheel/tire weight savings of 38 pounds. Pretty significant amount of rotating unsprung mass. Between that and the significant gearing benefit – these are 1.5″ (!) shorter than stock – the car should feel much lighter on its feet and pick up a lot of acceleration.

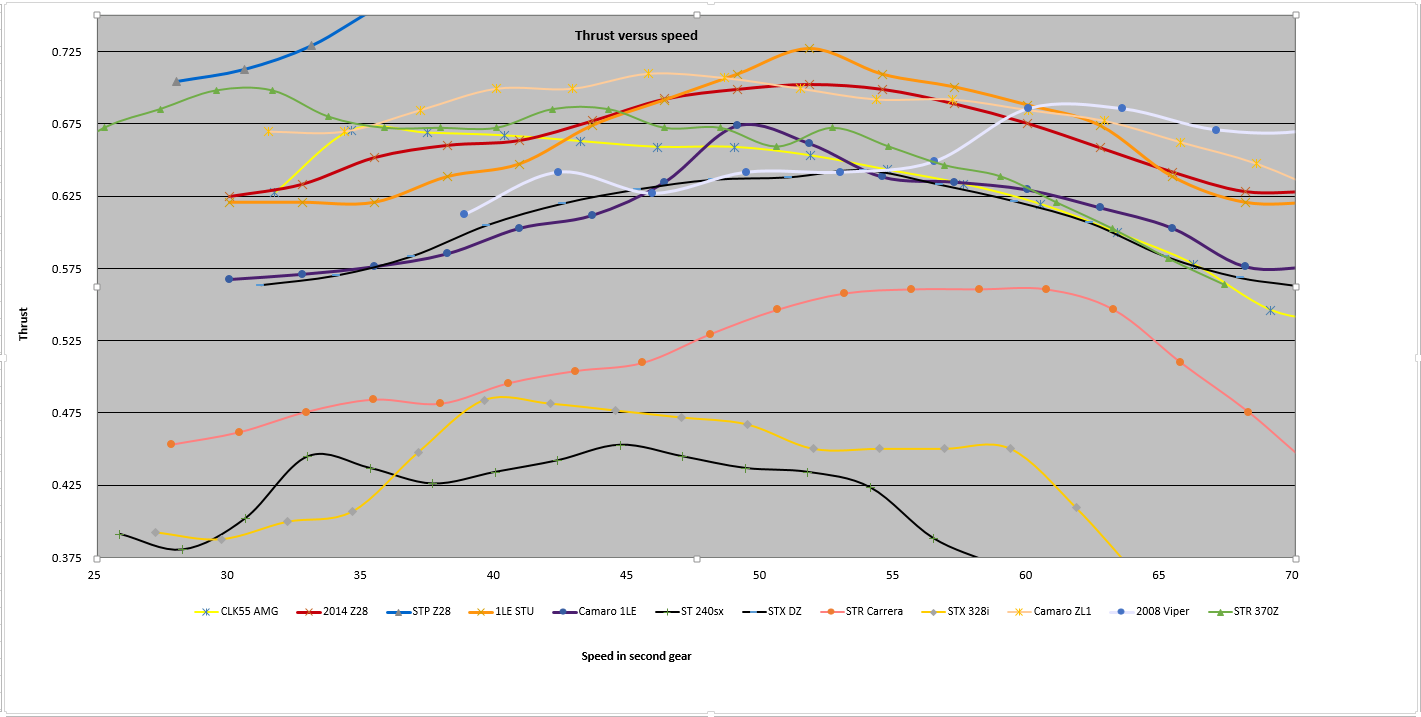

Speaking of acceleration – plugged some numbers into my master spreadsheet to see where the 370 would fall. You can ignore the other cars presented, with the exception of the 911 they aren’t STR cars-

I’ll look to get some other STR cars (S2000, NC Miata, Spyder) added at some point, but based on the raw values, thrust looks good. I imagine it’ll be more than the little 255’s can handle most of the time. The humps at low speed are encouraging, car should dig well out of the slow stuff. Didn’t know much about how the 370’s engine worked until recently, some pretty neat stuff there.

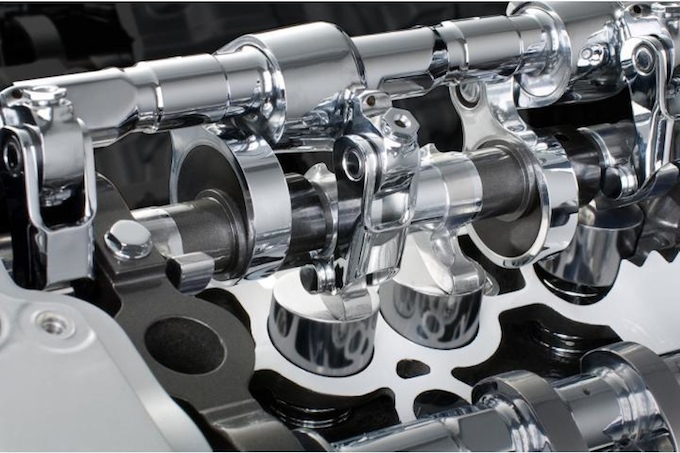

The VVEL system means the engine is throttled not by the throttle butterflies, but by how much the ECU lets the intake valves open through its wacky multi-fulcrum monkey motion. The throttle is fully open most of the time, which aids efficiency. Put it all together, Nissan has been able to produce a remarkably flat torque curve out of the motor, and it still responds well to tuning – here’s an example of one going from stock to a quality set of ST-style mods-

Back to the parts – in front of the wheel is a small XS Power lithium-ion battery. This is another leftover from the Camaro project, its “Nationals” battery:

It’s about 4 pounds, feels like an empty casing when you pick it up. The Z should have reliable enough electronics, there shouldn’t be a problem leaving this one in here full time. I leave the car on a tender anyway when not in use.

Leaning in front of the battery are a pair of terminal adapters so the stock power cables can attach. Not going to hassle with relocation. The stock battery is over 35 pounds, so this will mean 31 pounds off the nose, big win.

Next to the battery are a cocktail of Redline gear oils. These will be going in the transmission. One theme with the Z, is that everything tends to run hot. The factory provides an oil temp gauge which gets too high too quick. But trans fluid overheats, diff fluid overheats, power steering overheats. My car’s transmission has been a little notchy on 1-2 from new, especially when cold. One of the quarts is a little thin which should help when it’s cold – one is “normal”, and one is a little heavy to help protect things when it gets too hot. Hopefully this mix, all based on Redline’s quality synthetic bases, means the trans will work well and be protected from what it encounters.

My first event was a practice with the car, about 70 second runs on a warm (~95) degree day. I started a run with oil temp at 180 degrees. Came in, it was at 220. Cranked on the fans coming in, but went back out about 2 minutes later – coming in from that run, oil temp was over 240! Things start to get really bad for most oils around 250 degrees, and the car will go into “limp mode” (killing power and max RPM) by 260. Even though I let the car idle for a while with all the fans on to get it down to 205 before shutting off, it still spewed coolant all over its undertray-

Looks like a handful of Smurfs got sent through the fan blades…

Next to the gear oils – the brown cardboard box contains a 34-row Setrab oil cooler, which I believe is the biggest one available on the market. I’m hoping this helps keep things well under control for all autocross situations (including if I ever have a codriver at a ProSolo) and should make the car a bit more stable if I decide to try a track day in it.

On top of the box are the braided and sheathed oil cooler lines, and the baggies contain the various adapters and brackets to make it fit.

Behind the oil cooler are a pair of wheel spacers/adapters. I mentioned these in the last post, they’re what allows the 5×114.3 bolt pattern Z, to fit a 5×4.75 bolt pattern Camaro wheel. Pretty neat stuff, they were inexpensive too.

Behind those against the wall – a couple quarts of Redline gear oil for the diff. Need to replace the fluid when I change out the limited slip – with the part ahead of them in the blue box.

Quaife has been making robust torsen/gear-type limited slip differentials for a long time. They are great for cars that see regular street and track use, because on the street they don’t really make awful groans and chirps, and are low maintenance – while working great on the track/autocross in most applications. Their biggest downside is they don’t work well when one of the drive wheels gets unloaded – in that situation, it becomes like an open diff. Fortunately I don’t think the Z will have that problem.

The en vogue Street Touring diff these days is the OS Giken clutch-type. I’ve driven a few of them, as well as various other clutch-types, and when setup and tuned right, they are great. I think in an inherently neutral and well-balanced car like an S2000 or Miata, they make a lot of sense. However in the Z, which tends up push a lot, I’m not sure their characteristics are as desired. Plus the Quaife was on special, about half the price of the popular clutch-types.

On top of the Quaife box is a little red button. It’s a red engine start button from a GTR, a popular mod to replace the white button stock on the Z. My S2000 and Viper both had red start buttons, just keeping with that trend 🙂

Under the Quaife are a box of Kinetic adjustable front upper control arms. These have a bunch of adjustability – and can be modified for even more – to fix the Z’s biggest problem in street: lack of sufficient negative camber in front.

Forward of those things, are eight quarts of Redline motor oil. Will do an oil change as part of the cooler install. Went with a slightly heavier-than-stock viscosity – like most modern engines, factory fill is quite thin (0W20) – as the car won’t be driven often, it’s not going to see a ton of cold starts. Even with the cooler, the oil is bound to get hot when the car does get used, so the 40 part of 10W40 should protect it a bit better when things do get hot.

Behind the oil in bags, a pair of Berk high-flow cats for the car. The Z responds really well to this mod; probably half the power it picks up in ST trim comes from this one mod. The high flow cats also save a bunch of weight – will have to measure, but should be over 10 pounds.

There is an alternative path here – use of long tube headers, with the cats relocated back into the “y-pipe” behind the factory cat section. In this photo, you can see the heat shielding on the factory cat, and the flange to the y-pipe, on the passenger side. This photo is actually my car, was taken after it was loaded on the transporter for Nats earlier this year. The shiny stuff is the Garageline “midpipe” section – from the cats back to the stock muffler. Astounding value at like $300 – great sound (not too loud), nice x-pipe, and it de-restricts the worst part of the factory cat-back.

In ST we are allowed to relocate the cat up to 6″ downstream. This means one could conceivably use off-the shelf “longtube” headers, and put cats ahead of the flex pipe section in the above photo.

There’s a few things I’m leaving as considerations for future phases, and that’s one of them. At this point I’m not convinced the ones out there make any more midrange than stock manifolds + test pipes (or HFC). Top end, yes, but for a ton more $ ($1500+) and a ton of work – a header install on a 370 is supposed to be one of the most awful experiences ever – I’m ok putting that off for phase 2.

Last part is the box at far right – the Takeda cold air intake. This is similar in design to the Stillen G3 CAI that is super popular for this car – but in contrast, it doesn’t require cutting or modification of the car for installation.

Going to have to pull the nose off to do the oil cooler anyway, so can take care of this at the same time. I also like how Takeda played a part in sponsoring the No. 33 CA Sport/Skullcandy/Team Nissan 370Z run at the 25hr of Thunderhill endurance race, which ended today (the team finished third in class – in a car they just started on a couple weeks ago). Congrats to Bryan Heitkotter and the Skullcandy team!

So, those are the parts for now.

In addition to considering longtube headers for a future phase, there are also brake rotors (10lb/corner front, 5lb/corner rear, all for $1300) to get, and seats. The stock sport seats are all manual and weigh 42 pounds, so there’s only 17lb/side to save there. Even without these, the car should be around 3100lbs. with about 53% front weight.

With this car the idea is to keep the approach a bit more budget oriented, but also to make it a bit more of a street/race compromise. Want it to be something I wouldn’t dread hopping in and driving a great distance to an event. That’s what Street Touring is supposed to be about, especially with a newer car. Still only 600 miles on this one! This means I’ll be keeping the stock muffler (which doesn’t rob power but is ~20lbs. dead weight), stock motor and trans mounts, and going a little more gentle in rear spring rate than I otherwise might. When it’s time to do a race seat, will be looking for something with easier ingress/egress than a Cobra Suzuka.

Now it all just needs to get installed eh? 🙂

What’s up in the garage?

Sharp eyes will notice – that’s not a Camaro. With the car in the classing doldrums, needed something else to bide the time.

At the Farmington Pro in 2013 I saw a fellow named Mike running a 370Z in STR. It looked like a fun time – a new car, decent power, running in a fast class with DEEEEEP competition. It’s a bit hamstrung by somewhat heavy weight for the class limit wheel and tire, but well, that sorta thing I’m used to. Plus it’s a Nissan, I did well in one of those years ago, and I like the support they’ve given to amateur racers – including the GT Academy program and what it’s done for great guys like Bryan Heitkotter

Fast forward to July 2014 – Nationals approaching, nothing to run really. What the heck? Bought one thinking I’d run CS for a couple seasons, then move on to STR.

Did a practice then put it on a transporter to Nationals.

Did ok, 5th out of 50-something.

Then, the car got reclassed. Two years in a row, hah. It has to run against the C5 in BS now. Some people think it can get it done against the C5. I’m not one of them. 🙂

So, the STR plan got accelerated. Part of the overall plan with this car was not spending mega-$, trying to stick to that.

Sharp eyes may notice those wheels in the first pic, are the Camaro’s 18×9 Jongbloeds. 9″ is the maximum wheel width for STR. These are the wrong bolt pattern and have way too much offset for use on the Z. But – there are bolt-on spacers out there to adapt different bolt patterns. In this case, the spacer bolts on to the Z’s 5×114.3 (4.5″) hub, and presents a 5×4.75″ bolt pattern for the Camaro-pattern Jongbloeds. Two birds with one stone.

Still researching/plotting the rest of it, just where things are now. More to come later…

Camaro is tucked away safe and sound. The SCCA is still trying to figure out what to do with modified ponycars on street tires. Given its typical pace, should have plenty of time to get this thing dialed in.

Some images got wiped when the server went out, wanted something nice back on top-